These are 2 key companies providing HDPE to the marine industry. HDPE is replacing teak due to its UV resistance and zero maintenance requirements. I found Seaboard surface a little more resistant to scratches and use Mercury Grey color.

https://www.vycomplastics.com/product-families/seaboard/hdpe/

King StarBoard® | King Plastic Corporation

Most of my HDPE was done on CNC by Hein & Company from Hood River, he is a member on most van conversion forums. He is also a good source for the SM600 Thinsulate. There are many CNC fabs in US and they are not expensive as long you provide them with decent 2D or 3D CAD drawings. For simple straight cuts a simple table saw is good. To finish an edge with a router just use a roundover bit, works great.

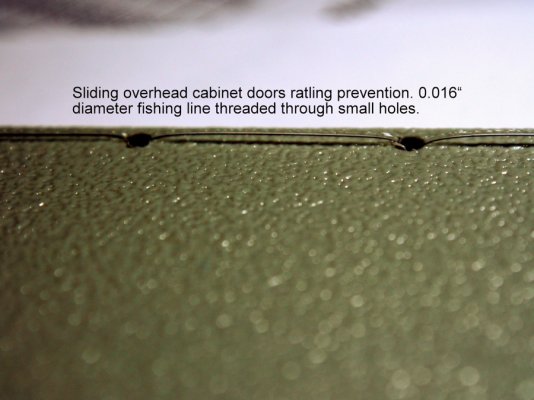

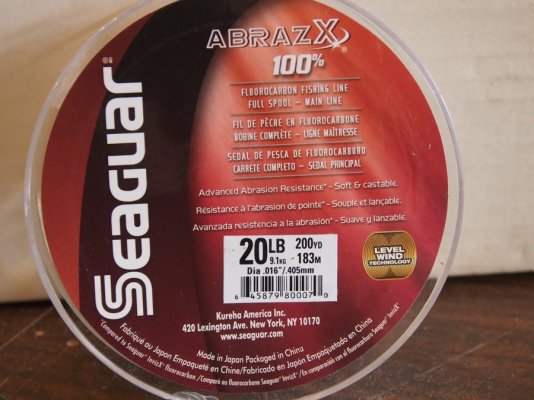

Rattling prevention:

I used a fishing line threaded through small drilled holes near the edge of the sliding door. It takes about 5 minutes to drill and 5 minutes to thread the fishing line so about 10 minutes/door. https://sprinter-source.com/forum/showpost.php?p=302772&postcount=498

If you would use plywood for sliding doors just glue a piece of thin felt on the inside, unfortunately there is no glue for polyethylene.

The grey silicon rubber is a panel seal from 80/20 #2178. Once properly inserted (a small flat scredriver) 1-inch pieces completely prevent vibration of ¼” HDPE panels and never come off.

https://www.vycomplastics.com/product-families/seaboard/hdpe/

King StarBoard® | King Plastic Corporation

Most of my HDPE was done on CNC by Hein & Company from Hood River, he is a member on most van conversion forums. He is also a good source for the SM600 Thinsulate. There are many CNC fabs in US and they are not expensive as long you provide them with decent 2D or 3D CAD drawings. For simple straight cuts a simple table saw is good. To finish an edge with a router just use a roundover bit, works great.

Rattling prevention:

I used a fishing line threaded through small drilled holes near the edge of the sliding door. It takes about 5 minutes to drill and 5 minutes to thread the fishing line so about 10 minutes/door. https://sprinter-source.com/forum/showpost.php?p=302772&postcount=498

If you would use plywood for sliding doors just glue a piece of thin felt on the inside, unfortunately there is no glue for polyethylene.

The grey silicon rubber is a panel seal from 80/20 #2178. Once properly inserted (a small flat scredriver) 1-inch pieces completely prevent vibration of ¼” HDPE panels and never come off.