To further muddy the water, interesting testing done by TBSS fellas: https://www.tbssowners.com/threads/factory-ev-fan-measurements-vs-measurements-of-ls1.14101/

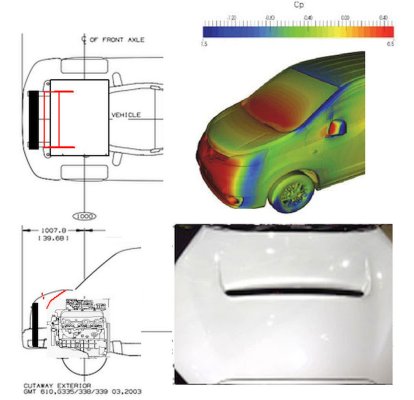

of note poster recorded in excess of 10,000 max CFM from the EV fan @3,000 rpm engine speed but despite this, TBSS was still prone to over heating... Easy to guess why though, TBSS has a tiny radiator - 18x26 - and a poor shroud design, whereas tahoe/suburban has same size as express - 34x17 - a 23% increase.

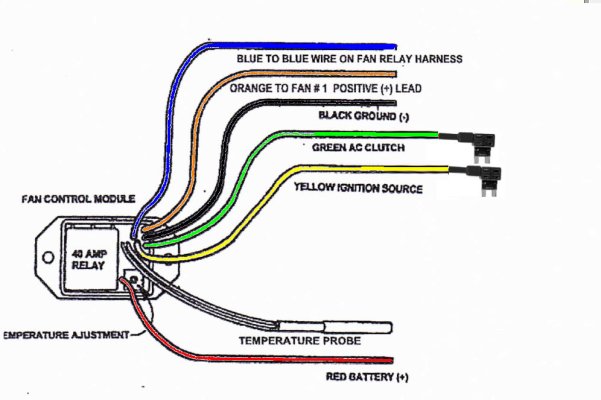

Back to 05+ tahoe setup, to resolve any doubts I had about the swap I performed a number of tests right after install. Normal Charleston morning with 89F and 80% humidity I idled the truck with AC off and fans disconnected. Eventually after 20 minutes or so the ECM finally commanded high speed but truck never overheated, just held 220. I then played with different relay and motor failures (standard 3 relay series/parallel setup) and even one fan on low was enough to keep it from overheating with the AC on full.

Either way, it seems tuning and shroud sealing (which I did a lot of) is key.

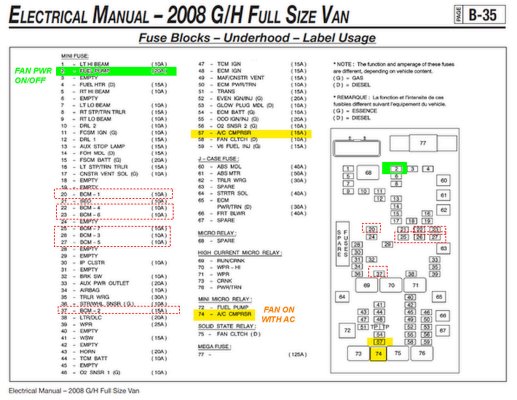

My fan tune was copied from stock tahoe which if I recall correctly called for low on @ 195, high on @ 210, low on AC request, high on AC high pressure, fans off over 45mph. I have yet to find any CFM ratings on the tahoe fan setup.

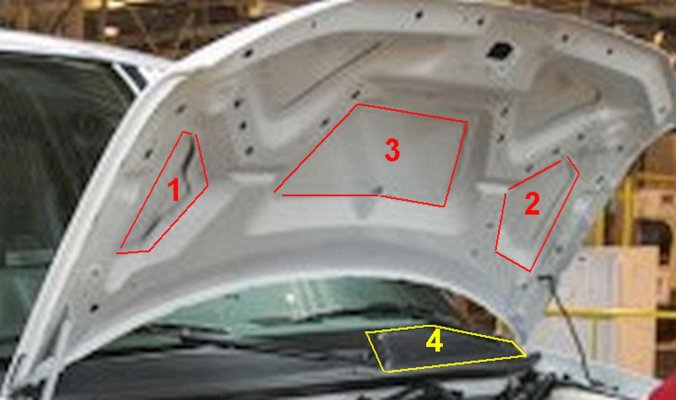

Just a note on the shrouds for the mechanical fans.

I used to mess around with some pretty nasty engine muscle cars like the twin turbo 340 cid Dodge Challenger that I built in the late 80s with all homemade stuff for turbo setup with carb and then aftermarket EFI. 600hp/600tq on a 5 speed Richmond trans. It was wonderful engine but the engine compartment was stuffed with hot stuff so hard to keep cool at idle because the air couldn't get out. I used every electric fan they had in those days and none would do the job either with a 4 core copper/brass radiator or a Griffen aluminum. The Griffen was great once moving but the electrics couldn't cut it at idle. I went back to a mechanical clutch fan with factory shroud and still had some issues.

The "rule of thumb" back then was to have the fan half in and half out at the rear of the shroud and that is where I had it. Checking airflow I found nearly all the movement coming off the blade ends with very little straight back toward the engine. I moved the fan back toward the engine so that the blades were only into the shroud about 1/4" and idle cooling issues went away completely. The airflow coming out from under the car sitting running was noticeably higher.

Today's cars with mechanical fans always have them tucked completely into the shroud, presumably, and wisely, for safety reasons. It does appear to cut down the flow a bunch. What can be done safely is to window out sections of the rear of the should and cover them with finger safe mesh to let the air out.

I really don't understand why GM turns on their fans at so high a temperature. I went through this on my 1996 Buick Roadmaster wagon that has the old reverse flow cooling 5.7 engine. The reverse flow makes the sensors and thermostat read differently, I think, so they are really high at 215 and 227*F, when the engine on thermostat runs about 198*. You get a constant cycling up and down that hot at stoplights and it is warm enough that in hot weather the alcohol laced fuel starts giving stutters at stop sign leaving. I tuned them down to 204 and 210* with my tuner where the 204 is just a bit above what the sensor sees on hot days at highway speeds and now it runs great all the time.

The Buick runs the small fan continuously when the AC is on and it never goes above about 202* it the hot weather. My high van essentially never comes on. This is with a 1.25" thick single core radiator which is the middle thickness of ones they offered on different cooling packages.

One thing to consider is that for as long as I can remember vans always run hotter than their full engine compartment cousins like pickups and SuVs. The small van engine compartment just can't get the air out fast enough, it appears. There is a discussion on here about adding side fender vents to let air out of the engine compartment, and I have considered doing it, but haven't to this point.