Sometimes crazy little ideas get out of hand and turn into bigger, crazier ideas, and sometimes those bigger crazy ideas actually work!

We put in an Isotherm compressor frig last year, and after bunches of messing with it (no help from Isotherm) we go it working well, using just 17amp-hr per day in moderate weather. With the electric only frig, battery capacity immediately becomes an issue and worry. A couple of things bugged me about the installation. One was that the frig light was still active when you turned the control knob to off, so you couldn't leave the door open when not in use unless you removed the bulb or pulled the fuse. Second was that we couldn't shut off the 12v power when we left the van for long periods. The detectors and other parasitic loads are about .25 amp, so it is very nice to save that power (3 amp-hr per day if you have the power off 12 hrs, which is very easy). The 3 way frig was the same way, as it needed 12v to run on gas, so this wasn't new.

It all started out to add an on/off switch, so the frig could be shut off completely. Since I had to pull a wire through the frig cabinet, I started thinking about running a wire to the coach batteries directly, so the frig could run without the 12v switch on. Got started on that, and then thought about making the added switch also be able to run the frig off the starting battery. It could easily spare 10 amp-hr a day for 3 days and still start the van, and then the 12v power could be left off to save the parasitic losses. Got started on that, and when I looked at the starting battery (OEM 64 amp-hr, 600 cranking), it looked really small in the battery tray. I pulled the battery out, did a little measuring, and found out the Chevy must still be using the 1970's battery tray (ours is an 07), because it is sized for a group 27 battery (diesel?). At that point, it went another step, to the thought of putting a big group 27 true deep cycle in place of the starting battery. We have two Trojan SC200, group 27 coach batteries,115 amps each, so why not add a third one in place of the starting battery. That would give us at least 60 amp-hrs of added capacity, although it would only be used for the frig, which is not much issue. 60 amp hours will run our frig over 3 days in moderate weather, and is a 33% increase in usable capacity from what we had (230 X 80% = 184). To try it out I put in one of the original Roadtrek coach batteries which is a 95 marine combo battery that is still OK, but not great. Of particular interest to me was that the Trojan SC200 has more cranking amps than the Chevy starting battery the van came with.

Finished it up today, with no more expansions or silly ideas. While I was at it, I replaced the temporay trim I had made for the frig and made a real switch panel for the compressor speed control and the new battery selector switch. Now I just wish it would quit snowing and get to be spring so we can give it a go and see what happens. Don't know if I will spring for another Trojan now or wait until the one I put in dies, we will see.

Here is what the battery looks like in place. It dropped right in and used the stock holddown perfectly. I used a set of top to side post adapters, and also put in my sidepost disconnect switch, which was good as it made up for a slightly too short positive cable.

There is a very easy connection point in the engine compartment fuse box. I used a ring terminal, and a 6mm nut to connect, and added a 10 amp weatherproof fuse setup.

I used a length of 14 gauge 4 wire trailer cable for the wiring. I only needed one wire, but as long as I had to run it, a few extras might be nice in the future. I put it in split sleeving, taped, and tie wrapped it to existing harness to just below the frig access panel. Easy run to there. To get the wiring up to the frig compartment, I got lucky that Roadtrek has an access port in the side storage compartment. I unscrewed it and pulling the wires into the frig compartment got really easy.

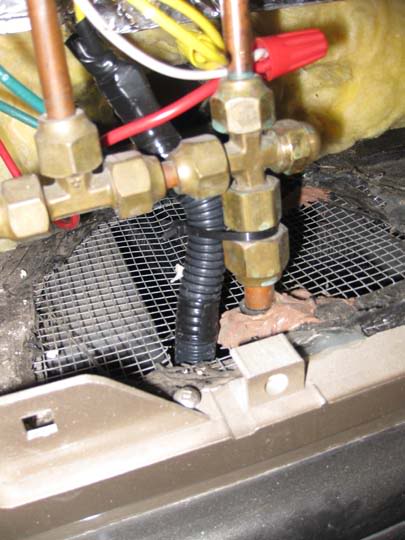

The wiring comes up through the lower air inlet screen into the compartment.

Another piece of the trailer harness, peeled to 3 wires runs to the front of the frig where the switches are and wires into the existing and new wires in the back of the frig compartment.

Mounted the new switch panel and trim.

Closeup of the switch panel. The upper knob controls the frig compressor speed, so we can vary the cooling capacity. The goal is to run it as slow as possible and still have it keep up, as it is much more efficient at the lower speeds. The bottom switch connects either to the coach batteries (through the 12 switch) or to the starting battery. Center is off so the frig can be totally shut down.

The whole setup, less battery, probably is less the $25. I had most of the stuff, so it was almost nothing for us. We would be due for a new starting battery in a year or two, and the big Trojan would only be about $60 more than a good starting battery. To be able to gain 60 amp-hrs of capacity, for under $100, and not have to find room for another battery and wiring, is my kind of return on investment. Total time was only about 3 hrs, if you don't include the trim and panel work.

I