|

|

08-14-2020, 10:40 PM

08-14-2020, 10:40 PM

|

#1

|

|

Platinum Member

Join Date: Jun 2020

Location: North Carolina

Posts: 132

|

Rhino Ramps

Rhino Ramps

Greetings fellow rv maintenance men/women,

-------Edit: these ramps are not a good idea after all. Do not buy them. I hadnt read the reviews about them breaking.

Now Im eating crow but letting yall know.

The Mityvac brake bleeder is still a solid, shop quality tool-----------------------

I have gotten good use out of a recent purchase:

The Rhino Ramps Max ramps, rated to 12000 lbs. They have a few versions, make sure you get the 12000 lbs version. Each ramp supports 3000 lbs.

https://www.walmart.com/ip/RhinoGear...acity/19526658

I have a sloped driveway and use the ramps to get the van almost level when I service our '12 Roadtrek 190. The directions for the ramps say not to use them for leveling for some reason but I have been.

---Edit--not a good idea using these on a slope/learn from my mistake-----

The Rhino ramps worked great for removing my non functioning (surprise, surprise) onan generator. Rolled the rvs rear wheels onto the ramps and had plenty of room to work.

The Rt 190s are low so these ramps make oil changes more pleasant.

I recently bled and flushed the brake fluid. This is a one man job and can be done in under an hour with this Mityvac brake bleeder. I highly recommend this compressed air driven, shop quality tool:

https://www.amazon.com/Mityvac-MV683...=fsclp_pl_dp_3

Working on your on vehicle can be fun....and necessary since some shops dont want to mess with (or cant lift) a 1 ton van. The quality of rv shop work that Ive seen receipts from the PO on have been troubling so I will do as much as I can myself.

-------In my haste to ready my rv for a trip I didnt thoroughly research the ramps. Do not buy them-----

Eric

__________________

2011 Roadtrek 190 "The Golden Shipping Container"

2004 Mazda Mazdaspeed Miata-handling and power

1989 Volvo 740Ti-dismachine

2014 Camry hybrid-soulless transport appliance

|

|

|

08-14-2020, 11:11 PM

08-14-2020, 11:11 PM

|

#2

|

|

Platinum Member

Join Date: May 2016

Location: LA

Posts: 1,551

|

The next time I'm ordering these, could have used them more than once.

Thanks Eric.

Bud

|

|

|

08-14-2020, 11:59 PM

08-14-2020, 11:59 PM

|

#4

|

|

Platinum Member

Join Date: Aug 2010

Location: Minnesota

Posts: 12,455

|

I also have heard of failed Rhino ramps, but no personal experience with them.

That said, I would never put a vehicle on any ramps on a sloped surface. It changes the weight distribution on the ramp itself and also puts in horizontal loads instead of the vertical only they are designed for.

|

|

|

08-15-2020, 12:12 AM

08-15-2020, 12:12 AM

|

#5

|

|

Platinum Member

Join Date: Nov 2014

Location: PHX, AZ

Posts: 2,660

|

I have set of steel ramps

Once up I place jackstands ( 4) under the frame rails

A family friend was killed working on his car. when it fell, he was by himself

Mike

|

|

|

08-15-2020, 12:39 AM

08-15-2020, 12:39 AM

|

#6

|

|

Platinum Member

Join Date: Oct 2006

Location: New Brunswick, Canada

Posts: 8,828

|

Forum member Ron posted that he was there when one of the 12k ramps failed after his son drove a pickup up on them & had stopped. No one was injured. I have a set of 12K Rhino Ramps (prior version) but I don't put the van up on them.

|

|

|

08-15-2020, 12:52 AM

08-15-2020, 12:52 AM

|

#7

|

|

Site Team

Join Date: Jul 2013

Posts: 5,428

|

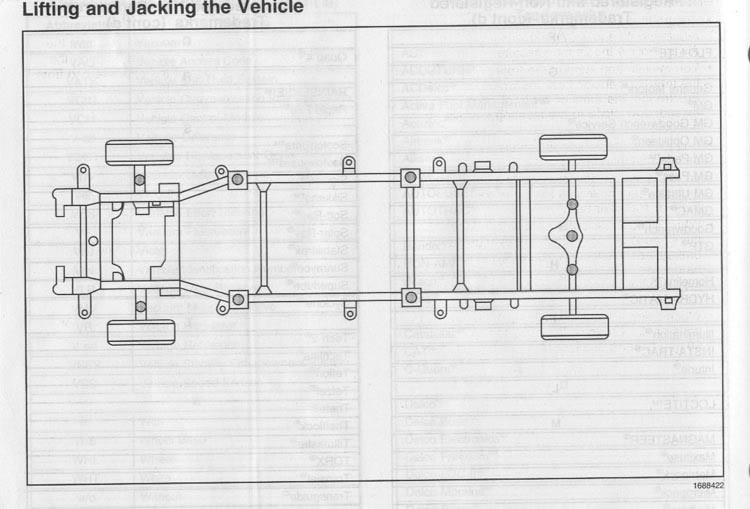

Make yourself a set of homemade wooden ramps, like this:

Lift f.jpg

Lift.jpg

Cheaper and vastly safer than anything you can buy.

__________________

Now: 2022 Fully-custom buildout (Ford Transit EcoBoost AWD)

Formerly: 2005 Airstream Interstate (Sprinter 2500 T1N)

2014 Great West Vans Legend SE (Sprinter 3500 NCV3 I4)

|

|

|

08-15-2020, 01:08 AM

08-15-2020, 01:08 AM

|

#8

|

|

Platinum Member

Join Date: Jun 2020

Location: North Carolina

Posts: 132

|

ramps

ramps

I missed typed, the ramps are rated to 3000 lbs a piece.

As far as failures, Ive used the passenger car version for years with no issues.

But using them on a slope, that was a crucial mistake.

Booster: I get your point about horizontal versus vertical loads.

Avanti: The wooden ramp idea is a good one. Are all the boards fastened together?

How are people lifting these vehicles at home without ramps? I didnt see any real promising lift point on the frame in the front. Center of the front subframe? Certainly can put a floor jack under the rear axle.

__________________

2011 Roadtrek 190 "The Golden Shipping Container"

2004 Mazda Mazdaspeed Miata-handling and power

1989 Volvo 740Ti-dismachine

2014 Camry hybrid-soulless transport appliance

|

|

|

08-15-2020, 01:46 AM

08-15-2020, 01:46 AM

|

#9

|

|

Platinum Member

Join Date: Aug 2010

Location: Minnesota

Posts: 12,455

|

Quote:

Originally Posted by MagicBox

I missed typed, the ramps are rated to 3000 lbs a piece.

As far as failures, Ive used the passenger car version for years with no issues.

But using them on a slope, that was a crucial mistake.

Booster: I get your point about horizontal versus vertical loads.

Avanti: The wooden ramp idea is a good one. Are all the boards fastened together?

How are people lifting these vehicles at home without ramps? I didnt see any real promising lift point on the frame in the front. Center of the front subframe? Certainly can put a floor jack under the rear axle.

|

GM removed the center lift point on the lower K frame in the redesign in 2003, it appears. The only lift points are the frame rails behind the front wheels, but they are right next to the tanks.

That said, I do lift from the K frame, but don't lift in the middle, which is it's weakest point. I put two 3 ton jacks under the K frame, just inside of where it turns up on the outboard ends. That has doublers on it and is nearly directly under the structure above it so very strong there. Downside is that it take two jacks, but I have always had a couple around my shop, even though I did have to upgrade to 3 ton from the two ton ones I had when we got the Roadtrek 190. I set it on jack stands of 3 ton capacity that are under the frame behind the front wheels. I lift the rear with a single 3 ton jack in the center of the axle and put stands under the axle tubes as far outboard as possible.

Don't skimp on lifting and supporting tools as a couple of bucks isn't work getting injured or dead.

Be aware that lifting with floor jacks is also something you have to be careful with as the jack has to be able to move as vehicle is lifted, because the lift arm pivots toward the handle. If the surface isn't good enough to roll on (even a tiny pebble can stop the rolling) you either will have the vehicle move or the jack will slide at the lift point. This is especially critical when lifting the second end if you are putting up the entire vehicle, which is mostly what I do. If the jack isn't able to roll easily, you can pull the vehicle off the stands on the other end, or at least tilt them up, so be very careful with that. I have seen a vehicle that had come off that way do to extreme stupidity of using stands and a floor jack on a gravel driveway  Ugly, but no one was hurt.

One thing that an old timer told me when I was in high school was that when on stands the vehicle should be able to be moved a little because the lifting center ratchet is a slip fit in the frame. If it moves a little you know that none of the stands is getting pulled on and supporting properly on all it's legs. It does seem very weird to be able to have it move a little when it is up in the air, but it sure seems he was right about that.

|

|

|

08-15-2020, 01:53 AM

08-15-2020, 01:53 AM

|

#10

|

|

Site Team

Join Date: Jul 2013

Posts: 5,428

|

Quote:

Originally Posted by MagicBox

Avanti: The wooden ramp idea is a good one. Are all the boards fastened together?

|

Yes. Just scrap pieces of 2x12, nailed together. You can get them very cheaply at the "cull" pile at Home Depot.

After using these for awhile, I would NEVER go back to any commercial ramps. Way too dangerous. If you use six of these, it is EXACTLY like sitting on your driveway.

__________________

Now: 2022 Fully-custom buildout (Ford Transit EcoBoost AWD)

Formerly: 2005 Airstream Interstate (Sprinter 2500 T1N)

2014 Great West Vans Legend SE (Sprinter 3500 NCV3 I4)

|

|

|

08-15-2020, 02:47 PM

08-15-2020, 02:47 PM

|

#11

|

|

Platinum Member

Join Date: Oct 2006

Location: New Brunswick, Canada

Posts: 8,828

|

+1 for wooden ramps

Mine are mostly made from scrap 1/2" plywood and OSB, all glued, screwed and nailed together as required. Height is 6.25". I needed a shallow entry to avoid pushing the ramps on the smooth concrete floor of the garage. There's 9" of ramp at less than 2" so it's easy to get the van up on them. I've had them for 7 years now.

I don't need the ramps as much since installing new Moog coil springs on the front and Air Lift bags on the rear. I can get under to do an oil change for example with no need for ramps.

My floor jack is barely adequate for van work so I use a bottle jack and stands if lubing the front end for example. I lift the van in stages until it's at the height I need. It takes more time than if using a suitable floor jack but not really a problem.

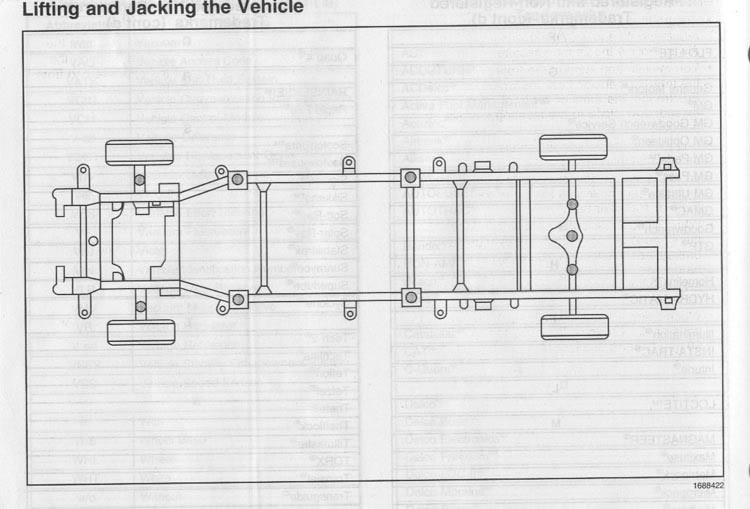

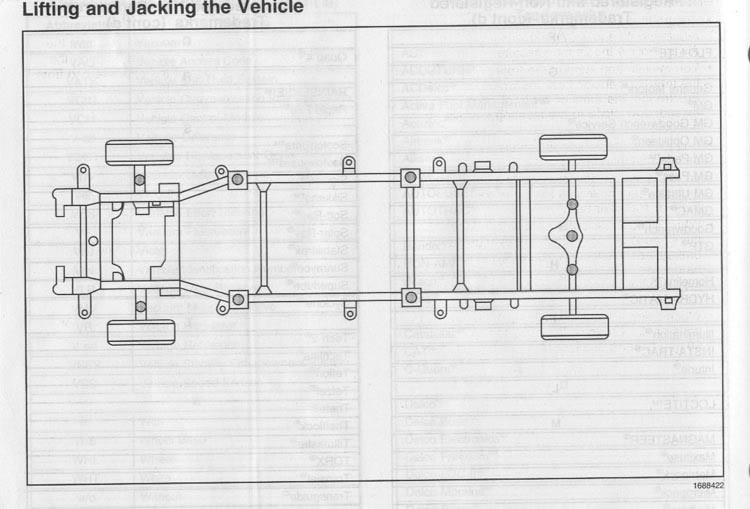

Booster mentioned that there are differences between '97-'02 vans and 2003 & newer. It looks as though 2003 & newer don't have the spot on the frame at the rear spring hanger:

1997 - 2002

2003 - newer (image provided by Booster)

If doing your own maintenance work then locating all the lube points is something you'll likely do. My 1997 GM van has 15 lube points (grease zerks) including one near the middle u-joint on the drive shaft.

Newer Chevy's (2003 and up) seem to have 11 lube points. Eric has a 2012 so could let us know if the number of lube points has changed.

|

|

|

08-15-2020, 03:08 PM

08-15-2020, 03:08 PM

|

#12

|

|

Platinum Member

Join Date: Dec 2016

Location: America's Seaplane City, FL

Posts: 1,000

|

Quote:

Originally Posted by markopolo

+1 for wooden ramps

Mine are mostly made from scrap 1/2" plywood and OSB, all glued, screwed and nailed together as required. Height is 6.25". I needed a shallow entry to avoid pushing the ramps on the smooth concrete floor of the garage. There's 9" of ramp at less than 2" so it's easy to get the van up on them. I've had them for 7 years now.

I don't need the ramps as much since installing new Moog coil springs on the front and Air Lift bags on the rear. I can get under to do an oil change for example with no need for ramps.

My floor jack is barely adequate for van work so I use a bottle jack and stands if lubing the front end for example. I lift the van in stages until it's at the height I need. It takes more time than if using a suitable floor jack but not really a problem.

Booster mentioned that there are differences between '97-'02 vans and 2003 & newer. It looks as though 2003 & newer don't have the spot on the frame at the rear spring hanger:

1997 - 2002

2003 - newer (image provided by Booster)

If doing your own maintenance work then locating all the lube points is something you'll likely do. My 1997 GM van has 15 lube points (grease zerks) including one near the middle u-joint on the drive shaft.

Newer Chevy's (2003 and up) seem to have 11 lube points. Eric has a 2012 so could let us know if the number of lube points has changed. |

Good info, thanks. I'm about to raise the front up on my wooden plank ramps to do a coolant flush.

__________________

Tick tock, baby(Ironbuttal)

2000 Roadtrek Chevy 200 Versatile(sold)

'98 Safari Trek 2480

Just for fun:'15 Kawasaki Versys650LT

Perfection is a fantasy, though improvement is possible(Wifey).

|

|

|

08-15-2020, 04:16 PM

08-15-2020, 04:16 PM

|

#13

|

|

Platinum Member

Join Date: Aug 2010

Location: Minnesota

Posts: 12,455

|

Quote:

Originally Posted by markopolo

+1 for wooden ramps

Mine are mostly made from scrap 1/2" plywood and OSB, all glued, screwed and nailed together as required. Height is 6.25". I needed a shallow entry to avoid pushing the ramps on the smooth concrete floor of the garage. There's 9" of ramp at less than 2" so it's easy to get the van up on them. I've had them for 7 years now.

I don't need the ramps as much since installing new Moog coil springs on the front and Air Lift bags on the rear. I can get under to do an oil change for example with no need for ramps.

My floor jack is barely adequate for van work so I use a bottle jack and stands if lubing the front end for example. I lift the van in stages until it's at the height I need. It takes more time than if using a suitable floor jack but not really a problem.

Booster mentioned that there are differences between '97-'02 vans and 2003 & newer. It looks as though 2003 & newer don't have the spot on the frame at the rear spring hanger:

1997 - 2002

2003 - newer (image provided by Booster)

If doing your own maintenance work then locating all the lube points is something you'll likely do. My 1997 GM van has 15 lube points (grease zerks) including one near the middle u-joint on the drive shaft.

Newer Chevy's (2003 and up) seem to have 11 lube points. Eric has a 2012 so could let us know if the number of lube points has changed. |

Good comparison pix. I am not sure on the rear spring hanger one as it may be the pix are just different wheelbase vans. The width to length ratio looks different from the 2003 to previous, with the 2003+ pic looking like an extended wheel base, which might change things. The center area lift points a commonly referred to as hoist pad contact points as that is what gets used for that purpose on post hoists, so the may show it closer to the front to keep balance and make sure they have enough reach in the support arms of the hoist.

Losing the front center lift point is a big deal, but I can tell you that many shops still lift there on the late vans, as they did on ours when we had the front springs put in. With the big cutout in the center of the frame, that just doesn't sound like a good idea on a 4300# axle fully loaded to that weight.

|

|

|

08-15-2020, 05:44 PM

08-15-2020, 05:44 PM

|

#14

|

|

Platinum Member

Join Date: Jul 2018

Location: Texas

Posts: 2,651

|

When I relocated my lithium batteries inside, I repurposed the old outside battery storage for my wood leveling blocks. I carry 6 - 2"x 8" blocks (trimmed to just under 7" width to fit in the old battery tray) and still have room for a plastic container with jumper cables and other emergency supplies.

I've never considered ramps for the reasons previously stated. Too many reviews of failures.

|

|

|

08-20-2020, 06:05 PM

08-20-2020, 06:05 PM

|

#15

|

|

New Member

Join Date: Jun 2020

Location: Fort Worth

Posts: 15

|

Quote:

Originally Posted by MagicBox

.......

But using them on a slope, that was a crucial mistake.

Booster: I get your point about horizontal versus vertical loads.

......

|

Are you saying any ramp on a sloped driveway is a bad idea or just the Rhinos?

I have a 20-25 degree angle on my driveway and was just recently thinking of building some ramps to level the van (Sprinter) for just general access comfort when dinking around inside. Not so much for going underneath.

Input is appreciated.

|

|

|

08-20-2020, 06:47 PM

08-20-2020, 06:47 PM

|

#16

|

|

New Member

Join Date: Jun 2011

Posts: 5

|

I have a set the 12k Rhino ramps (came with my tow dolly), my Roadtrek (02 Popular on Chevy chassis) has sat on these for over a month last year while I did the bodywork, no issues. If I'm going to be under the van I also support with a floor jack or post style hydraulic jack. (sometimes both jacks) My driveway is flat

Brian

Mississauga, ON

|

|

|

08-20-2020, 11:35 PM

08-20-2020, 11:35 PM

|

#17

|

|

Platinum Member

Join Date: Mar 2018

Location: WA

Posts: 259

|

With the mild ride height increases from tire and suspension improvements on our van, I am able to crawl around underneath it pretty well without having to use ramps, but when removing a wheel I use a 3.5 ton floor jack to lift it, and then support with at least two 3 ton jack stands (one as a fallback in case of a failure). I lower the van onto the jackstands and then pump the floor jack back up until it has a little bit of pressure on it (as an additional fallback). I'm very paranoid about jack failure.

__________________

2017 Winnebago Paseo

|

|

|

08-20-2020, 11:49 PM

08-20-2020, 11:49 PM

|

#18

|

|

Platinum Member

Join Date: Aug 2010

Location: Minnesota

Posts: 12,455

|

Quote:

Originally Posted by BillsPaseo

With the mild ride height increases from tire and suspension improvements on our van, I am able to crawl around underneath it pretty well without having to use ramps, but when removing a wheel I use a 3.5 ton floor jack to lift it, and then support with at least two 3 ton jack stands (one as a fallback in case of a failure). I lower the van onto the jackstands and then pump the floor jack back up until it has a little bit of pressure on it (as an additional fallback). I'm very paranoid about jack failure.

|

You are rightly concerned about a jack failure, as all it takes is one torn seal or broken relief valve to come down very quickly

I do the same as you do, lift with 3.5 ton jacks and two 3 ton stands in the proper places, stabilize with the jack a lot of time, unless I am going to put it all the way up on 4 stands.

|

|

|

08-22-2020, 04:43 PM

08-22-2020, 04:43 PM

|

#19

|

|

Gold Member

Join Date: Feb 2018

Location: PA

Posts: 76

|

When we got our B we also got some heavy duty ramps. No comparison to the rhino ramps - but when we do something we go overboard.

These are the ramps we got and have put the B up on them a few times for maintenance.

https://www.amazon.com/gp/product/B0...?ie=UTF8&psc=1

https://www.amazon.com/gp/product/B0...?ie=UTF8&psc=1

|

|

|

08-22-2020, 05:17 PM

08-22-2020, 05:17 PM

|

#20

|

|

Platinum Member

Join Date: Mar 2018

Location: WA

Posts: 259

|

Quote:

Originally Posted by pasusan

When we got our B we also got some heavy duty ramps. No comparison to the rhino ramps - but when we do something we go overboard.

These are the ramps we got and have put the B up on them a few times for maintenance.

https://www.amazon.com/gp/product/B0...?ie=UTF8&psc=1

https://www.amazon.com/gp/product/B0...?ie=UTF8&psc=1 |

Wow, those are some serious ramps! I wouldn't be worrying about a ramp collapsing with a set of those!

__________________

2017 Winnebago Paseo

|

|

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

|

» Recent Threads

» Recent Threads |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|