|

|

12-02-2019, 12:13 AM

12-02-2019, 12:13 AM

|

#41

|

|

Platinum Member

Join Date: Feb 2019

Location: Blairsville Ga

Posts: 174

|

Quote:

Originally Posted by SteveJ

How would a fuel tank not let in atmospheric air as the level draws down? It would either collapse from the vacuum if the pump could pull it or would have to have a pressurized bladder system, similar to a water pressure tank.

Pretty much the only time one would see condensation in a modern headlight assembly is if it's damaged or defective.

Most phones are not sealed.

|

It's fairly simple you remove the air and replace it with gasoline vapors!

"Gasoline readily evaporates at normal ambient temperatures and it also degrades over time from oxygenation and condensation. In order to ensure that the gasoline in the tank does not hurt the Volt’s performance or emissions engineers pressure sealed the 9.3 gallon steel fuel tank to contain the gasoline vapors. The tank has a mechanical pressure relief valves to control pressure."

|

|

|

12-02-2019, 12:47 AM

12-02-2019, 12:47 AM

|

#42

|

|

Platinum Member

Join Date: Aug 2007

Location: Minnesota

Posts: 5,967

|

I don't know how many upfitter's install lithium batteries now outside a B van other than mine, early ARV install, and EHGNA. Who knows what Rapido will really resurrect. They don't have much knowledge in lithiums so could repeat the Ecotrek mistakes. However, I never read about problems with batteries on the outside from EHGNA. Sealed cases are difficult with conduit penetrations. As well as my case was sealed, early on if on a warm day and hitting a cooling rainstorm my batteries did short out until they dried again. It was sudden atmospheric pressure differential that caused sucking moisture in or condensation. ARV fixed it by simply installing a button sized Gortex plug in the enclosing fiberglass case to equalize the pressure. The problem hasn't come back now for four years.

It was more common to install wet cell lead acid and AGMs outside in non-sealed compartments and moisture discussions I don't remember, but they never had the computer board chips attached that I recall.

ARV's Volta system and Valence lithium systems are installed inside. Most DIY lithium systems are installed inside that I have seen.

__________________

Davydd

2021 Advanced RV 144 custom Sprinter

2015 Advanced RV Extended body Sprinter

2011 Great West Van Legend Sprinter

2005 Pleasure-way Plateau TS Sprinter

|

|

|

12-02-2019, 12:56 AM

12-02-2019, 12:56 AM

|

#43

|

|

Platinum Member

Join Date: Aug 2010

Location: Minnesota

Posts: 12,457

|

I would think a totally sealed outside cabinet with in and out ventilation (forced if needed) to the interior would give the best way to have them be outside. Box could be very well insulated, wouldn't require heat most of the time, unless the van was not in use, and would not accumulate moisture any worse than being inside the van. Saving space is a big deal in a lot of vans.

|

|

|

12-02-2019, 01:01 AM

12-02-2019, 01:01 AM

|

#44

|

|

Site Team

Join Date: Jul 2013

Posts: 5,428

|

Quote:

Originally Posted by IdleUp

It's fairly simple you remove the air and replace it with gasoline vapors!

|

Although it is true that gasoline vapor can produce positive pressure, it is also true that even small drops in ambient temperature can produce significant vacuum (a drop of only 3°F will reduce vapor pressure by 1"-H2O. Modern vehicles have very complex self-checking evaporative control systems as part of the emissions control suite. They have several valves and sensors and behave in complex ways under various conditions. These systems always include vacuum relief valves which do indeed let air into the tank when circumstances dictate.

If you want to drink from a fire hose on this topic, here is a good reference:

https://www.motor.com/wp-content/uploads/032015_6.pdf

__________________

Now: 2022 Fully-custom buildout (Ford Transit EcoBoost AWD)

Formerly: 2005 Airstream Interstate (Sprinter 2500 T1N)

2014 Great West Vans Legend SE (Sprinter 3500 NCV3 I4)

|

|

|

12-02-2019, 01:45 AM

12-02-2019, 01:45 AM

|

#45

|

|

Platinum Member

Join Date: Dec 2016

Location: America's Seaplane City, FL

Posts: 1,000

|

Quote:

Originally Posted by booster

Unless they have changed them headlights are also vented to prevent pressure build up from heat. The van and my Buick have a small rubber elbow on the back of the lamp.

|

Makes sense. I'll stand corrected. That said, I've never had composite headlights get condensation in them and there is plenty of humidity in FLA.

__________________

Tick tock, baby(Ironbuttal)

2000 Roadtrek Chevy 200 Versatile(sold)

'98 Safari Trek 2480

Just for fun:'15 Kawasaki Versys650LT

Perfection is a fantasy, though improvement is possible(Wifey).

|

|

|

12-02-2019, 02:00 AM

12-02-2019, 02:00 AM

|

#46

|

|

Site Team

Join Date: Jul 2013

Posts: 5,428

|

If I were installing lithium batteries, I would likely use exactly the same system that I have now courtesy of GWV: Boxes recessed below the floor and accessed through floor hatches. The GWV battery boxes have vent holes (placed there to ventilate FLA batteries, no doubt). I would forgo them in this application, and maybe install small computer fans to circulate warm inside air. I would apply insulation outside the boxes and add the standard heating pads for frigid conditions. I am quite sure this would work fine.

__________________

Now: 2022 Fully-custom buildout (Ford Transit EcoBoost AWD)

Formerly: 2005 Airstream Interstate (Sprinter 2500 T1N)

2014 Great West Vans Legend SE (Sprinter 3500 NCV3 I4)

|

|

|

12-02-2019, 04:34 PM

12-02-2019, 04:34 PM

|

#47

|

|

Platinum Member

Join Date: Feb 2019

Location: Blairsville Ga

Posts: 174

|

Quote:

Originally Posted by SteveJ

Makes sense. I'll stand corrected. That said, I've never had composite headlights get condensation in them and there is plenty of humidity in FLA.

|

Headlights use an inert gas like Argon or Xenon therefore contain no air to support condensation and do not suffer from condensation as a lithium battery incased in plastic or worse thin metal case as most are manufactured. The metal components in Lithium is extremely sensitive to even small amounts of moisture in the air. Exposure to moisture results in reduced performance and cell life. Moisture is even more critical during manufacturing, where the environment is controlled to less than 2% humidly for this reason. Condensation in lithium housings occurs in open, sealed and liquid cooled battery packs. Water vapor acts as a catalyst to lithium. All lithium cells suffer to a degree from moisture.

Whenever possible, lithium installations should always be located in a semi-controlled environment in the coach and not in outside compartments or cavities in the floorboards. These areas are all subject to quick climate changes, which produce condensation. Even driving through a quick rain storm temperatures can drop 20-30 degrees in minutes changing the batteries case temperature creating interior condensation. The more stable the batteries temperature remains, the less condensation occurs. As I mentioned in my tread, there is also capacity benefits when stored in controlled environment. Lithium batteries will provide more power when operating in their designed 68 degree temperature.

On all my lithium installations, I install 300 watt marine heaters which heats the entire compartment as well as heat the battery uniformly. On the installation image below, this heated area is vented into the interior of the coach to retain safe interior temperatures, avoiding common freezing problems to some RV components.

Even though I fully winterize the coach, for decades I always used marine heaters since they help avoid sudden temperature changes. Having a controlled temperature in the coach also avoids rapid temp changes which results in interior sweating. This helps preserve the composite wall materials and fabrics.

Mike

|

|

|

12-02-2019, 05:12 PM

12-02-2019, 05:12 PM

|

#48

|

|

Platinum Member

Join Date: Feb 2016

Location: Portland, Oregon

Posts: 3,307

|

Quote:

Originally Posted by IdleUp

Headlights use an inert gas like Argon or Xenon therefore contain no air ....................

[/IMG]

|

Old sealed beams just like any other incandescent light bulbs have inert gas to prevent burning of tungsten filament. But headlights, they are full of air, just like many articles on internetS.

|

|

|

12-02-2019, 06:33 PM

12-02-2019, 06:33 PM

|

#49

|

|

Platinum Member

Join Date: May 2016

Location: LA

Posts: 1,551

|

Quote:

Originally Posted by GeorgeRa

Old sealed beams just like any other incandescent light bulbs have inert gas to prevent burning of tungsten filament. But headlights, they are full of air, just like many articles on internetS.

|

Hi George,

Reading your post, well it dawned on me - why Idleup is here.

Idleup has told us his stuff/writing is Triple Fact Checked. This forum is his Quadruple Fact Checker.

Bud

|

|

|

12-02-2019, 07:00 PM

12-02-2019, 07:00 PM

|

#50

|

|

Platinum Member

Join Date: Aug 2010

Location: Minnesota

Posts: 12,457

|

Quote:

Originally Posted by IdleUp

Headlights use an inert gas like Argon or Xenon therefore contain no air to support condensation and do not suffer from condensation as a lithium battery incased in plastic or worse thin metal case as most are manufactured.

Mike

|

It is the BULBS that are sealed with inert gas in them, the headlight lamps are not, and are intentionally ventilated.

Note the circles in the pic.

They are not sealed. This ain't rocket science.

|

|

|

12-02-2019, 09:06 PM

12-02-2019, 09:06 PM

|

#51

|

|

Site Team

Join Date: Jul 2013

Posts: 5,428

|

Sigh... Where to start?

Quote:

Originally Posted by IdleUp

Headlights use an inert gas like Argon or Xenon therefore contain no air to support condensation and do not suffer from condensation

|

Air does not "support condensation" any more than "inert gasses" do. Water vapor can condense, no matter what it is mixed with. No water vapor, no condensation.

Quote:

|

as a lithium battery incased in plastic or worse thin metal case

|

Thin metal cases are near perfect vapor barriers. I repeat: sealed containers CANNOT EXPERIENCE CONDENSATION.

Quote:

|

The metal components in Lithium is extremely sensitive to even small amounts of moisture in the air. Exposure to moisture results in reduced performance and cell life. Moisture is even more critical during manufacturing, where the environment is controlled to less than 2% humidly for this reason. Condensation in lithium housings occurs in open, sealed and liquid cooled battery packs. Water vapor acts as a catalyst to lithium. All lithium cells suffer to a degree from moisture.

|

More nonsense.

It is precisely BECAUSE lithium is so sensitive to water vapor (which it is) that all functioning lithium batteries are guaranteed to be hermetically-sealed. If this weren't true, they wouldn't work. THERE CANNOT BE CONDENSATION INSIDE A FUNCTIONING LITHIUM CELL And, if the hermetic seal is broken, the battery will soon destroy itself.

Quote:

|

Whenever possible, lithium installations should always be located in a semi-controlled environment in the coach and not in outside compartments or cavities in the floorboards. These areas are all subject to quick climate changes, which produce condensation.

|

Not if they are sealed or ventilated.

Quote:

|

Even driving through a quick rain storm temperatures can drop 20-30 degrees in minutes changing the batteries case temperature creating interior condensation.

|

I wonder what the specific heat of 60Kg of lithium battery is? Do we know why that matters?

__________________

Now: 2022 Fully-custom buildout (Ford Transit EcoBoost AWD)

Formerly: 2005 Airstream Interstate (Sprinter 2500 T1N)

2014 Great West Vans Legend SE (Sprinter 3500 NCV3 I4)

|

|

|

12-03-2019, 12:01 AM

12-03-2019, 12:01 AM

|

#52

|

|

Platinum Member

Join Date: Feb 2016

Location: Portland, Oregon

Posts: 3,307

|

Quote:

Originally Posted by avanti

………………………….

Thin metal cases are near perfect vapor barriers. I repeat: sealed containers CANNOT EXPERIENCE CONDENSATION.

More nonsense.

It is precisely BECAUSE lithium is so sensitive to water vapor (which it is) that all functioning lithium batteries are guaranteed to be hermetically-sealed. If this weren't true, they wouldn't work. THERE CANNOT BE CONDENSATION INSIDE A FUNCTIONING LITHIUM CELL And, if the hermetic seal is broken, the battery will soon destroy itself.

|

Chemical reaction between water and lithium is exothermic and hydrogen is generated, so a bum-bum is more likely than just self-destruction.

|

|

|

12-04-2019, 01:37 PM

12-04-2019, 01:37 PM

|

#53

|

|

Platinum Member

Join Date: Jan 2014

Posts: 131

|

Quote:

Originally Posted by nebulight

........ the main component for stopping charge below freezing is my Victron Battery Monitor BMV712 as it has a built in relay that can be triggered by a number of conditions (temp being the one I'm using).........

|

I use SOC to trigger the BMV712 relay to stop charging. I was wondering if you used any other condition as well as temperature to trigger the relay and, if so, how you set the parameters?

|

|

|

12-05-2019, 06:31 AM

12-05-2019, 06:31 AM

|

#54

|

|

Platinum Member

Join Date: Feb 2016

Location: Portland, Oregon

Posts: 3,307

|

It seems as IdleUp went to IdleDown, this is a good news.

|

|

|

12-05-2019, 12:43 PM

12-05-2019, 12:43 PM

|

#55

|

|

Platinum Member

Join Date: May 2016

Location: LA

Posts: 1,551

|

Quote:

Originally Posted by GeorgeRa

It seems as IdleUp went to IdleDown, this is a good news.  |

Seems that no Quadruple Fact Checker is needed at this time.

Bud

|

|

|

12-05-2019, 06:23 PM

12-05-2019, 06:23 PM

|

#56

|

|

Platinum Member

Join Date: Oct 2006

Location: New Brunswick, Canada

Posts: 8,828

|

Quote:

Originally Posted by Davydd

..................... The individual cells ranged from 3.35V to 3.39V and the cell temperatures were reported at 53 to 55 deg. which was just slightly above the room temperature......................

|

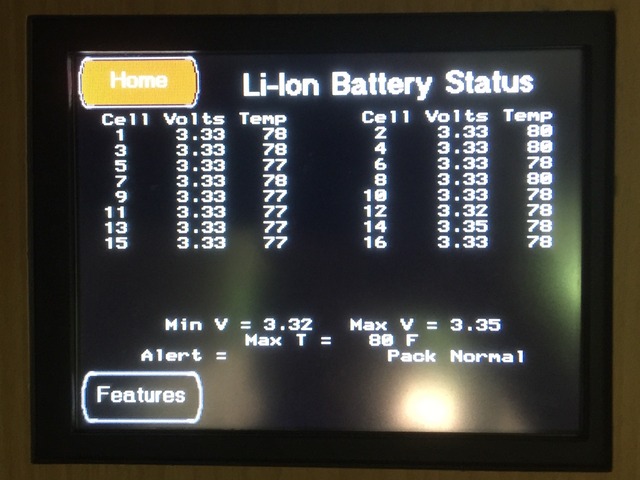

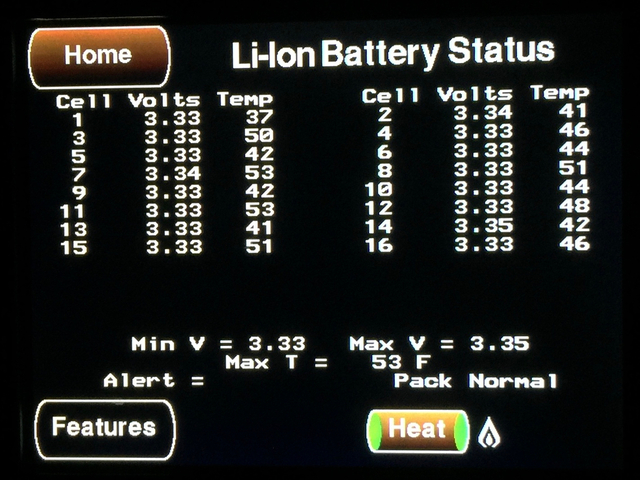

I'm sort of focusing in on balancing voltage tolerance and what it should be set at and was wondering if you could post a current photo of the Silverleaf screen with a similar 4/100ths of a volt difference between some cells.

I think these two previous Silverleaf screen shots are in date order:

then

It would be interesting to see which cells differed from the rest this time.

Do you know which cell numbers are in which 12v grouping? Do cell numbers 1,2,3 & 4 form one 12v grouping for example?

|

|

|

12-06-2019, 12:49 AM

12-06-2019, 12:49 AM

|

#57

|

|

Platinum Member

Join Date: Aug 2007

Location: Minnesota

Posts: 5,967

|

Marco,

I don't know the arrangement other than four in series make up one 12V 200ah battery and then four batteries in parallel make up one block of 800ah. I would guess the batteries are in sequence in that cells 1-4 make up one 12V battery and then 5-8, 9-12 and 13-16. I think that because of the temperatures and this photo showing uneven heating pads leaving cells 1, 5, 9 and 13 colder in the block. That's all I can go on. The heat will not turn off until that last cell 1 reaches 41 degrees F. The two photos were taken before and after my Silverleaf program upgrade. Before I only had a physical toggle switch to turn the heating pads on and didn't know if they were actually working. Now I have a touch screen button that shows with the green handles that heat is armed and the flame symbol that indicates heat is actually being applied. The flame symbol comes and goes.

The voltage reading is a range as shown. I don't know what ARV programs but it says "Pack Normal" for those ranges shown. I've only observed balancing just once in 5 years and don't remember the details other than the batteries got way hotter than normal.

__________________

Davydd

2021 Advanced RV 144 custom Sprinter

2015 Advanced RV Extended body Sprinter

2011 Great West Van Legend Sprinter

2005 Pleasure-way Plateau TS Sprinter

|

|

|

12-07-2019, 01:12 PM

12-07-2019, 01:12 PM

|

#58

|

|

Platinum Member

Join Date: Oct 2006

Location: New Brunswick, Canada

Posts: 8,828

|

I'd like to know more about the voltage difference between cells. From the photos it was 30mV max and 20mV but your latest report indicated the max spread was now 40mV.

I wonder at what point does cell voltage variance become a concern?

Would initiating top balancing now lessen the variance? How long would that effect last?

These are just general questions - I'm not in any way suggesting that there's a problem with Davyyd's battery bank.

|

|

|

12-07-2019, 02:04 PM

12-07-2019, 02:04 PM

|

#59

|

|

Platinum Member

Join Date: Aug 2010

Location: Minnesota

Posts: 12,457

|

Quote:

Originally Posted by markopolo

I'd like to know more about the voltage difference between cells. From the photos it was 30mV max and 20mV but your latest report indicated the max spread was now 40mV.

I wonder at what point does cell voltage variance become a concern?

Would initiating top balancing now lessen the variance? How long would that effect last?

These are just general questions - I'm not in any way suggesting that there's a problem with Davyyd's battery bank.

|

I have the same type of questions as it is starting to appear that things like the balancing and kind of unclear memory things may all be kind of interconnected when it comes to some of the other things we have seen like narrowed operating ranges and lowered charge voltages. The balancing seems to in the middle of most of the things, though, and at this point there is not a lot of information on how is best to address it on an ongoing and in use basis, or even how bad is bad.

For instance, if a unit had automatic top balancing on each cycle, like some seem to do, would that also take care of some/most/all of the memory effect things?

Or the opposite, if you are careful about running a full charge and full discharge at some, yet unknown, frequency, would that eliminate the need to have separate balancing cycles?

We don't know how much imbalance is needed before it is a real issue, I think, and we have seen very little actual cell voltage information over time as most systems don't show it and parallel connections likely hide some imbalance unless disconnected to check.

Hopefully in the near future some clarity to what some of the interactions are between all these things really is, as it seems to be a bowel of spaghetti now, to me.

|

|

|

12-07-2019, 07:07 PM

12-07-2019, 07:07 PM

|

#60

|

|

Platinum Member

Join Date: Aug 2007

Location: Minnesota

Posts: 5,967

|

Quote:

Originally Posted by markopolo

I'd like to know more about the voltage difference between cells. From the photos it was 30mV max and 20mV but your latest report indicated the max spread was now 40mV.

I wonder at what point does cell voltage variance become a concern?

Would initiating top balancing now lessen the variance? How long would that effect last?

These are just general questions - I'm not in any way suggesting that there's a problem with Davyyd's battery bank.

|

ARV had to program the acceptable range as they did say "Pack Normal" in those photos. I have no idea what the range is. Keep in mind those photos and a few others I have had SOC's less than 100%. Maybe I should catch it when it is 100% SOC to see what the numbers are. As I mentioned I've only observed balancing once in five years. Whether it occurs more frequently I don't know. But I did know because the Silverleaf screen was jumping up and down with numbers and the battery heat was higher than normal and I called ARV in panic thinking it was something else and they assured me the cells were going through a balancing phase.

I have ARV's first Elite Power Solutions build of 800ah lithium batteries. They've since said Elite has improved their BMS (which I don't have) and this battery pack is their lowest offering with Valence and Volta being more desired. After 5 years I have no complaints and the performance of the batteries appear no different. I think that ARV white paper kind of explains that as there is a 20% cutoff programmed in.

__________________

Davydd

2021 Advanced RV 144 custom Sprinter

2015 Advanced RV Extended body Sprinter

2011 Great West Van Legend Sprinter

2005 Pleasure-way Plateau TS Sprinter

|

|

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

|

» Recent Threads

» Recent Threads |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|