|

11-13-2019, 01:34 AM

11-13-2019, 01:34 AM

|

#1

|

|

New Member

Join Date: Oct 2018

Location: NJ

Posts: 9

|

Yet another hybrid Lithium install

Yet another hybrid Lithium install

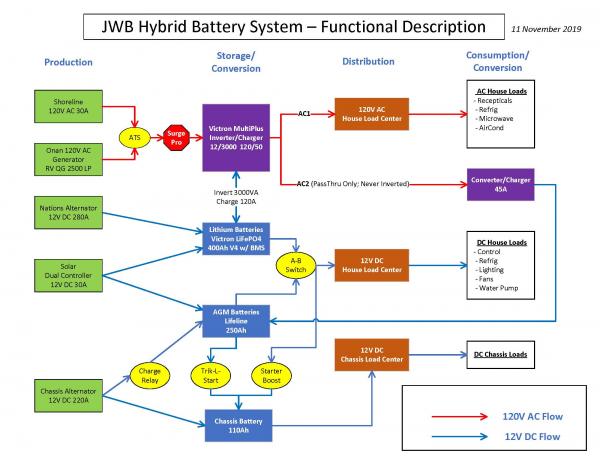

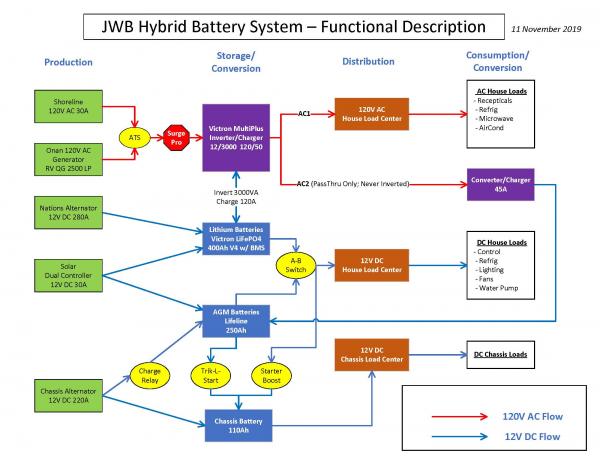

I too embarked on a hybrid Lithium installation. My goals were a bit different than some others, as I wanted to have the AGM system and the Lithium system primarily isolated from each other: “two is one and one is none.” In this way, the vehicle can be used in Winter Mode using the AGM bank, and in Summer Mode with the Lithium Bank. A Blue Sea Marine A-B switch (make before break) installed in the passenger seat pedestal allows switching between modes. Because the Lithiums are installed inside the vehicle, when it is warm enough for me to be comfortable inside the vehicle it is warm enough to utilize the Lithium bank.

AGM System: The AGM install consists of two new Lifeline GPL-31XT 125Ah batteries (total 250Ah) installed under the body in the stock Winnebago boxes. Blue Sea terminal fuses were added at each location. These charge from the stock 45A converter/charger when on shore power or from the Onan generator.

Lithium System: The Lithium install consists of two new Victron LiFePo V4 200Ah batteries (total 400Ah), installed under the starboard bunk. It is a tight squeeze, requiring removal of one drawer and adding a ventilation grille (for air flow and to camouflage the hole where the drawer was). A battery tray was welded up from angle stock, and through-bolted to the floor for crash-worthiness. A new Victron MultiPlus 12/3000W PSW inverter/charger keeps these charged when on shore power, and feeds inverted AC to the [almost] entire stock AC load center when on battery power (to retain the automated load shedding capabilities Winnebago built in). (The AC input to the stock 45A converter/charger that charges the AGM bank was removed from this load center, and instead is fed through the AC-2 output of the Victron inverter (which only passes AC and is never inverted), to avoid a death-loop. Thus, the AGMs only charge from shore power or the Onan generator, never from the inverter or the Lithium batteries.)

A Nations 280XP 280A alternator was added under the hood, and wired to the Lithium bank via 4/0 cabling. A dash switch allows you to turn the alternator off or place it in low-power mode, and dash indicators monitor its state.

The entire mess was terminated using two Victron Lynx Distribution panels with requisite fusing. Because I apparently suffer from an obsessive/compulsive disorder, each input and output is separately fused and runs through a manual Blue Sea Marine disconnect switch, as well as through automated relays getting instruction from an AM Solar BMS, to control appropriate charges and loads based upon Lithium battery temperature and other operating conditions. [Shout out to AM Solar, who patiently endured countless idiotic questions from me and supplied much of the hardware at competitive pricing.] There is a fairly complex Lithium qualification loop I created, which is probably clearer from the schematics than text will allow here.

AC Management: The stock ATS toggles between shore power and the stock Onan generator, and then feeds a new Progressive Industries hardwired EMS (with remote display) to monitor and qualify incoming AC power, before it is routed to the AC systems. These each run through Blue Sea circuit breakers too. When the Onan generator is running, its trigger output is fed to the Victron inverter signal inputs to automatically limit maximum current usage accordingly.

Solar: The stock Zamp single channel solar controller was replaced with a dual channel model, which isolates its two outputs and feeds each bank separately while never allowing cross-talk. I recognize that the Zamp is only a PWM controller, and is somewhat less efficient than a comparable MPPT controller. However, given the massive charging sources we have from the Victron inverter/charger and the Nations alternator, solar is merely an afterthought – primarily coming into use when the vehicle is parked somewhere off-grid while we are hiking. We generally do not boondock for extended periods, instead moving around frequently, allowing the underhood generator to quickly provide most charging we need. This is especially true given that Winnebago installed only 200W of solar panels, and littered the roof with things in an aggressively-haphazard topography that leaves very little room for more panels. Finally, the new Zamp controller was able to fit in the old panel cutout perfectly, making it the clear choice!

Monitoring: A Digital MultiControl GX panel and pair of Victron BMV-712 battery monitors (with separate shunts on each of the AGM and Lithium banks) allow me to keep an eye on everything.

Miscellaneous: I deemed the stock Start-Assist (a/k/a Boost) switch inadequate for our split system, so a new circuit and switch, using a second relay, was crafted. Flyback diodes were utilized on all relays. A Trik-L-Start was added, with a cutout switch and separate fusing.

If my wife asks, the system was quite economical.

For completeness, vehicle is a 2017 Winnebago ERA 70A (2016 Sprinter EXT chassis) fairly stock, which we purchased used in November 2018 with approximately 4K miles.

Thank you.

|

|

|

11-13-2019, 01:36 AM

11-13-2019, 01:36 AM

|

#2

|

|

New Member

Join Date: Oct 2018

Location: NJ

Posts: 9

|

|

|

|

11-13-2019, 01:37 AM

11-13-2019, 01:37 AM

|

#3

|

|

New Member

Join Date: Oct 2018

Location: NJ

Posts: 9

|

|

|

|

11-13-2019, 01:38 AM

11-13-2019, 01:38 AM

|

#4

|

|

New Member

Join Date: Oct 2018

Location: NJ

Posts: 9

|

|

|

|

11-13-2019, 01:50 AM

11-13-2019, 01:50 AM

|

#5

|

|

Platinum Member

Join Date: Jul 2018

Location: Texas

Posts: 2,651

|

Class "b's" are really tight on space. Nice use of the small area you had available.

|

|

|

11-13-2019, 02:57 AM

11-13-2019, 02:57 AM

|

#6

|

|

Platinum Member

Join Date: Feb 2016

Location: Portland, Oregon

Posts: 3,307

|

Well done, what is your plan for Li batteries storing in frigid conditions?

|

|

|

11-13-2019, 03:26 AM

11-13-2019, 03:26 AM

|

#7

|

|

Platinum Member

Join Date: Dec 2010

Posts: 2,058

|

Quote:

Originally Posted by GeorgeRa

Well done, what is your plan for Li batteries storing in frigid conditions?

|

frigid conditions outside with wind would probably never be frigid enough inside to require doing anything but turning off i would think

|

|

|

11-13-2019, 03:59 AM

11-13-2019, 03:59 AM

|

#8

|

|

Silver Member

Join Date: Oct 2019

Location: Pennsylvania

Posts: 52

|

That’s really neat that you’re using the genset features of the multiplus. Did you consider going to 24v? If so, what caused you to decide to stick with 12v?

|

|

|

11-13-2019, 12:29 PM

11-13-2019, 12:29 PM

|

#9

|

|

Platinum Member

Join Date: Aug 2010

Location: Minnesota

Posts: 12,456

|

Very nicely done, and particularly that it is done with standalone lithium batteries and separate BMS control which appear to give more thorough control and monitoring than the built in BMS setups that are locked up internally in the drop in batteries. Do you happen to know whose BMS that AM Solar is using? In the past, many/most of the products they have with their name on them are good quality private label parts so probably here also. AM Solar folks are good people for sure.

I haven't had time to scour the wiring drawings, which are very nicely done by the way (what program were they done on), to this point but don't see the solar panels with a disconnect to the controller, which you may want to consider if there is not one. With the main solar shutoff you could unreference the controller I think while under solar input.

|

|

|

11-13-2019, 07:10 PM

11-13-2019, 07:10 PM

|

#10

|

|

New Member

Join Date: Oct 2018

Location: NJ

Posts: 9

|

Thank you all for the interest. Let me try to answer some questions.

Voltage: I stayed with 12V as I was only installing 400Ah, and therefore the highest voltage I could go with as a practical matter was 24V. In my mind, benefits of 24V would at best be a marginal decrease in wire size, which would then be offset by needing device(s) to handle the DC-DC conversion back to 12V for the various coach loads, as I was not going to change out every device. If I was building the coach from scratch (and I have thoughts/dreams of doing exactly that some day) and adding a lot more storage capacity, I would have strongly considered a higher voltage system, perhaps 48V. That high of a voltage creates a far more substantial set of benefits over 12V (or 24V), while the offsetting burdens remains the same (converting 48V to 12V is really no different than converting 24V to 12V).

Cold Storage: I agree that allowable temperature range is the current Achille's heel of Lithium batteries, and something we considered greatly before the install. I am lucky enough to have a barn behind my house that fits the RV when not on the road. Although unheated and uninsulated, it is cement floored and relatively tight, and temps inside rarely go low enough to worry about battery storage temp inside the vehicle (in coastal New Jersey). And because there is a dedicated 30A shoreline for the RV in the barn, I could set a simple ceramic heater on the floor inside the back of the coach if I was worried about some unusual cold snap. Given the battery location right behind the louvered grate in the cabinet, I'm sure even a tiny heater could keep things sufficiently toasty. (Cue Davydd to remind me that power failures often accompany cold snaps, and that ARV therefore installs a backup sterling-silver sterno chafing pan under each lithium battery they install.  )

When the vehicle is in use, if it is warm enough for us to be in it then it is warm enough for the Lithium batteries to be used for all purposes. We are travelers rather than sit-in-one-placers, so even if we are out of the vehicle it won't be for more than a few hours, and the Truma can remain running at a moderate setting without fear of running out of propane. And if it does, the BMS will shut down the batteries.

The only nightmare scenario would be visiting frigid Saskatchewan and blowing a transmission, whereupon the vehicle has to sit outside a repair facility for days or weeks. I'm not really staying up nights worrying about that, and will handle that if it occurs.

The RV is in the barn right now, with the A-B switch turned to Winter/AGM, so the various coach loads are not on the Lithiums. Charging and loads should be managed to safe levels by the BMS. [Note the clever transition here.]

BMS: The battery management system actually consists of three separate components working together: (i) a Victron VE.Bus BMS; (ii) a temperature probe; and (iii) the AM Solar Lithium Control Board. My neophyte understanding of these three devices is as follows.

The Victron BMS is on a comm bus that daisy-chains to each battery, and reads cellular level data re over-voltage, under-voltage, and over-temperature. The BMS can then report out two discrete signals, charge-disconnect (in the case of over-temperature or over-voltage) and load-disconnect (in the case of under-voltage), which can then be acted upon by other devices, such as external switching equipment or chargers. Note that under-temperature is NOT one of those reportable conditions. Why that is so is a mystery to me and, to my addled brain, is a major flaw in the Victron system (for which, luckily, there is a work-around). And Victron, if I'm wrong, please feel free to correct me.

The temperature probe attaches to the post of the Lithium battery, and reports, you guessed it, Lithium battery temperature. To my understanding, this probe is the first half of the work-around, being necessary because the Victron BMS does not report out under-temperature conditions.

The AM Solar Lithium Control Board is a small PC board that reads the two triggers from the Victron BMS (charge-disconnect and load-disconnect), as well as the temperature from the external temp probe, and two other external triggers from the vehicle (ignition signal and boost signal). The LCB then (I'm guessing) uses a bunch of AND-gates and OR-gates to logically combine and manage the various input triggers to provide a half-dozen external signals that can control external equipment, including relays. For example, when conditions appropriate, the LCB will output an "alternator" signal that allows the external Balmar MC-614 regulator to energize the field of the Nations 280XP alternator, allowing charging to occur. If an over-current condition is reported, this "alternator" signal will go low, whereupon the field of the alternator will safely collapse and cease charging the Lithium batteries (without the damage that would be done if, for example, the high-output from the alternator instead ran through relay contacts that were interrupted). Similarly, the LCB will interrupt power to a "load" relay, causing house loads to be removed, for example, when battery voltage or temperature is too low. While this sounds simplistic, it is simple but brilliant, in that it takes the many inputs and determines to what the Lithium batteries should and should not be connected under those conditions. Because there are a variety of separate outputs, by observing the logic you can customize the control points in your system to a very granular level (and AM Solar discloses the underlying logic in a simple document). I am unsure whether the AM Solar Lithium Control Board is actually built by them, or rebranded, but they speak about it using words like "ours," and I have not seen a board of similar function or form. When I was building in 1Q19 they were in the process of changing from Ver 4.2 to 4.3, but I chose to go with the old one as it seemed at first blush easier for me to implement my more complex alternator qualification loop.

[Mods, feel free to delete this sentence if in any way contrary to posting guidelines:] AM Solar was excellent to work with, and seemed interested in even do-it-yourselfers like me being successful, and their LCB was a big part of my success (I finished my install in April but waited until now to report on it to see if anything burned down in the intervening six months  ).

Solar Voltage Reference: The Zamp controller has two discrete outputs. Solar charge from only one leg is disconnected from the Lithiums by a charge-disconnect relay when the BMS/LCB says it should, while the second output remains attached to the AGMs. (And this is even a redundant fail-safe mode, as the Zamp controller reads the Lithium voltage and should back down of turn off current to that output if the Lithium voltage is too high.) Thus, even if the BMS/LCB cuts off the solar charge, the Zamp controller remains attached to the AGMs and retains reference.

The Blue Sea manual disconnect, indeed, disconnects both outputs of the solar controller from both battery banks, and therefore the controller would lose reference. This manual switch is only there for if/when I am working on the bus (pun intended) and need to have it totally dead. It is possible that output from the panels could still be going into the controller, which without reference might, might, create some sort of havoc. But, given how seldom this might be, and the really low cost of the Zamp controller, I am not inclined to worry too greatly. (There are circuit breakers between the panels and the controller.)

GenSet Signal: I'm glad you liked this aspect, as I too thought it one of the more imaginative (but trivial to implement) elements. The MultiPlus and Digital MultiControl GX allow you to identify the current capacity of the shoreline with a panel dial, so as to not exceed that ceiling by limiting charge and other loads. The MultiControl also contains a pair of contacts which when closed tell the system that you are not on shore power but instead on the GenSet, and allow you to program in the current capacity of that generator, so that whenever the GenSet is running it automatically overrides the potentially-higher (yup, another pun) panel limit and instead limits current to the "GenSet" limit.

Most installations use a set of aux contacts on the ATS to implement this, but my ATS lacks those aux contacts and I did not want to buy ( OK, my wife wouldn't let me buy) yet another component for solely this purpose. Then I realized that the Onan GenSet sends a 12V+ signal to the Winnebago multiplex wiring system when running, to increment the hour meter. I merely tapped into that signal with a small relay, and used that relay to close the contacts on the MultiControl GX. Now, when the generator starts, the extant current limit on the digital display turns from "25" or "30" to "GEN," and I smile a little (thinking that no one else would understand my giddiness, and now I know you do; thank you).

Schematics: All done in Vizio, my first use of the program.

Thank you all.

|

|

|

11-13-2019, 10:06 PM

11-13-2019, 10:06 PM

|

#11

|

|

Platinum Member

Join Date: Mar 2012

Location: Maryland

Posts: 1,197

|

Nice job - looks like a great project. Visio is great for schematics. I used it when I was working. I just wish it wasn't so expensive. $280 for Standard and $530 for full featured Professional version.

__________________

2024 Airstream Interstate 19

|

|

|

11-13-2019, 10:10 PM

11-13-2019, 10:10 PM

|

#12

|

|

Platinum Member

Join Date: Aug 2010

Location: Minnesota

Posts: 12,456

|

Quote:

Originally Posted by Boxster1971

Nice job - looks like a great project. Visio is great for schematics. I used it when I was working. I just wish it wasn't so expensive. $280 for Standard and $530 for full featured Professional version.

|

Is that a per year or one time price? So many nice programs are going yearly that it is tough to find decent stuff these days.

|

|

|

11-13-2019, 10:37 PM

11-13-2019, 10:37 PM

|

#13

|

|

Site Team

Join Date: Jul 2013

Posts: 5,428

|

Quote:

Originally Posted by Boxster1971

Nice job - looks like a great project. Visio is great for schematics. I used it when I was working. I just wish it wasn't so expensive. $280 for Standard and $530 for full featured Professional version.

|

If you are a Mac or iPad user, Omnigraffle is a good choice.

https://www.omnigroup.com/omnigraffle/

Not too expensive.

__________________

Now: 2022 Fully-custom buildout (Ford Transit EcoBoost AWD)

Formerly: 2005 Airstream Interstate (Sprinter 2500 T1N)

2014 Great West Vans Legend SE (Sprinter 3500 NCV3 I4)

|

|

|

11-14-2019, 03:58 AM

11-14-2019, 03:58 AM

|

#14

|

|

Platinum Member

Join Date: Mar 2012

Location: Maryland

Posts: 1,197

|

Quote:

Originally Posted by booster

Is that a per year or one time price? So many nice programs are going yearly that it is tough to find decent stuff these days.

|

Those are the one time buy prices. For Plan 1 (std) is $5/mo with one year commitment or $6/mo without. Plan 2 (Pro) is $15/mo or $18/mo.

__________________

2024 Airstream Interstate 19

|

|

|

11-14-2019, 01:05 PM

11-14-2019, 01:05 PM

|

#15

|

|

Platinum Member

Join Date: Aug 2010

Location: Minnesota

Posts: 12,456

|

Vizio does look nice but a bit rich for my blood

Back to the new system.

I think it might benefit a lot of us if the OP could give us a run down of what the charge profiles look like and where they are controlled.

With two monitors, solar controller, shore charger etc there are likely many options.

How the AGM bank is handled to prevent over or undercharging would be of particular interest, as it would normally be full and just sitting so would not want a things like a solar charge cycle every day on top of full. Same true when going on shore power.

|

|

|

11-14-2019, 03:26 PM

11-14-2019, 03:26 PM

|

#16

|

|

Platinum Member

Join Date: Aug 2007

Location: Minnesota

Posts: 5,967

|

Quote:

Originally Posted by JWBrown

Thank you all for the interest. Let me try to answer some questions.

Cold Storage: I agree that allowable temperature range is the current Achille's heel of Lithium batteries, and something we considered greatly before the install. I am lucky enough to have a barn behind my house that fits the RV when not on the road. Although unheated and uninsulated, it is cement floored and relatively tight, and temps inside rarely go low enough to worry about battery storage temp inside the vehicle (in coastal New Jersey). And because there is a dedicated 30A shoreline for the RV in the barn, I could set a simple ceramic heater on the floor inside the back of the coach if I was worried about some unusual cold snap. Given the battery location right behind the louvered grate in the cabinet, I'm sure even a tiny heater could keep things sufficiently toasty. (Cue Davydd to remind me that power failures often accompany cold snaps, and that ARV therefore installs a backup sterling-silver sterno chafing pan under each lithium battery they install.  )

When the vehicle is in use, if it is warm enough for us to be in it then it is warm enough for the Lithium batteries to be used for all purposes. We are travelers rather than sit-in-one-placers, so even if we are out of the vehicle it won't be for more than a few hours, and the Truma can remain running at a moderate setting without fear of running out of propane. And if it does, the BMS will shut down the batteries.

The only nightmare scenario would be visiting frigid Saskatchewan and blowing a transmission, whereupon the vehicle has to sit outside a repair facility for days or weeks. I'm not really staying up nights worrying about that, and will handle that if it occurs.

The RV is in the barn right now, with the A-B switch turned to Winter/AGM, so the various coach loads are not on the Lithiums. Charging and loads should be managed to safe levels by the BMS. [Note the clever transition here.]

Thank you all. |

Thank you for your very thorough well thought out system in regard to cold weather. You answered all my questions. I responded in another thread and investigated low temperatures for Pennsylvania and found Philadelphia's low was only -7F so without checking coastal New Jersey I imagine you are safe. I had an uninsulated detached garage in my old house in Minnesota and found the temperature inside was usually about 15-20 degrees above ambient from radiating constant winter ground temperatures of 57F in the winter. I think you are safe. I now store in a condo garage with heat set at 45F. My gas furnace doesn't come on because the owners on both sides and the back must keep their garages warmer and that radiating thing from the ground helps as well.

My current van has lithium batteries outside the cab in an insulated box with electric heating pads when I stored outside. They kept them above 41F so they could accept a charge and I was plugged into shore power. I never had a power failure but the first week I had the van I discovered my my on/off heating switch was wired backwards (I didn't know it) and my heating pads were off in -5F conditions. So I rigged up emergency heat with like this until I figured it out. So you weren't too far off on your sterno chaffing dish.

Belts and suspenders. My next van is going to have LiFeMgPo4 lithium manganese batteries that can be stored down to -40F (-40C) which is the same as some reference say AGM batteries are good for. So Saskatchewan here I come.

Our new van batteries will also be under the bed inside, so underway one can assume one heats a van for comfort and naturally keep them above freezing. Since I don't envision ever storing outside again and will travel mostly in above freezing conditions, I haven't discussed the possibility of applied direct heat for storage. When plugged into shore power your batteries will have a temperature above ambient of about 10F degrees. It is the battery temperature that is the concern and not the ambient (air).

I think this is about covers lithium ion in cold temperatures between the two of us including the Chicken Little scenarios. Bottom line is if you have lithium batteries I think it is foolish if you don't have an electrical source of just 120V AC 15A shore power where you store when not in use in most of the United States if it gets down to -4F, if only for emergency purposes. I think you can camp the same climate as with any other van. We done it to -15F and several times down -0F boondocking.

__________________

Davydd

2021 Advanced RV 144 custom Sprinter

2015 Advanced RV Extended body Sprinter

2011 Great West Van Legend Sprinter

2005 Pleasure-way Plateau TS Sprinter

|

|

|

11-19-2019, 06:23 PM

11-19-2019, 06:23 PM

|

#17

|

|

New Member

Join Date: Oct 2018

Location: NJ

Posts: 9

|

Quote:

Originally Posted by booster

... I think it might benefit a lot of us if the OP could give us a run down of what the charge profiles look like and where they are controlled.

With two monitors, solar controller, shore charger etc there are likely many options.

How the AGM bank is handled to prevent over or undercharging would be of particular interest, as it would normally be full and just sitting so would not want a things like a solar charge cycle every day on top of full. Same true when going on shore power.

|

At the outset, recall that one of my design decisions was to isolate (except for Trik-L-Start and boost functions) the AGM and Lithium banks, so that there is no battery-to-battery charging between them. Each discrete system is as follows:

Lithium Bank: The Lithium bank is charged from the Nations 280XP alternator while underway, from the Victron Inverter/Charger when on shore power or the GenSet is running, and from the Zamp solar controller.

The Nations alternator can output to 280A, but via the Balmar external regulator I have it detuned approximately 30% (through the field reduction settings of the Belt Load Manager). Additionally, the optional temp sensor is installed, so the regulator automatically will further reduce its output if it gets too hot. And I also installed a dash switch that allows for low-power mode, or even off, to reduce engine load when desired (for example, while chugging up a steep, long mountain road). Other Balmar regulator settings include:

- Battery type: Lithium

- EQ mode: No

- Bulk: 14.3V x 6 min

- Absorb: 13.6V x 18 min

- Float: 13.4V x 18 min – 6 hrs

The Victron is programmed:

- Charge current: 120A

- EQ mode: No

- Absorb: 14.2V x 1 hr

- Float: 13.5V

The Zamp solar controller Output 1 is programmed for LiFePO4, which yields (unalterable):

- EQ mode: No

- Bulk: 10-14V

- Absorb: 14.4V x 4 hr or ≤ 0.5A

- Float: 13.6V

AGM Bank: The AGM bank and its charging systems and parameters are (except for 25% greater storage capacity and better brand of battery) exactly as Winnebago installed. It charges from the OEM Sprinter alternator while underway, from the Progressive Dynamics Inteli-Power PD 9200 Converter/Charger when on shore power or the GenSet is running, and from the Zamp solar controller.

The Inteli-Power 9200 produces (unalterable):

- Boost Mode: 14.4V only if voltage is “low” (exact spec unstated)

- Normal Mode: 13.6V

- Storage Mode: 13.2V, when device senses no significant usage x 30 hrs,

Then 14.4V x 15 min every 21 hrs

The Zamp solar controller Output 2 is programmed for AGM, which yields (unalterable):

- EQ mode: No

- Bulk: 10-14V

- Absorb: 14.4V x 4 hr or ≤ 0.5A

- Float: 13.6V

Coordination, or Not: Booster correctly notes that, when in Lithium mode, the AGMs are largely sitting there full, and when in AGM mode the Lithiums are similarly full.

There is NO coordination between the various charging sources, other than the individual voltage and current triggers that inform each. I rely, perhaps foolishly, on the presumption that full batteries will appear to each charging source as full, and therefore not trigger a complete charging cycle. I believe that charging voltages are also fairly conservative, to minimize over charging conditions. For example, float voltages on the Lithium bank are 13.6V or less, which seems to comport with most trending best practices.

Happy to hear thoughts of those who think there is a need for improvement.

|

|

|

11-21-2019, 06:57 PM

11-21-2019, 06:57 PM

|

#18

|

|

Bronze Member

Join Date: Nov 2013

Location: AL

Posts: 35

|

Quote:

Originally Posted by JWBrown

I too embarked on a hybrid Lithium installation. My goals were a bit different than some others, as I wanted to have the AGM system and the Lithium system primarily isolated from each other: “two is one and one is none.” In this way, the vehicle can be used in Winter Mode using the AGM bank, and in Summer Mode with the Lithium Bank. A Blue Sea Marine A-B switch (make before break) installed in the passenger seat pedestal allows switching between modes. Because the Lithiums are installed inside the vehicle, when it is warm enough for me to be comfortable inside the vehicle it is warm enough to utilize the Lithium bank.

AGM System: The AGM install consists of two new Lifeline GPL-31XT 125Ah batteries (total 250Ah) installed under the body in the stock Winnebago boxes. Blue Sea terminal fuses were added at each location. These charge from the stock 45A converter/charger when on shore power or from the Onan generator.

Lithium System: The Lithium install consists of two new Victron LiFePo V4 200Ah batteries (total 400Ah), installed under the starboard bunk. It is a tight squeeze, requiring removal of one drawer and adding a ventilation grille (for air flow and to camouflage the hole where the drawer was). A battery tray was welded up from angle stock, and through-bolted to the floor for crash-worthiness. A new Victron MultiPlus 12/3000W PSW inverter/charger keeps these charged when on shore power, and feeds inverted AC to the [almost] entire stock AC load center when on battery power (to retain the automated load shedding capabilities Winnebago built in). (The AC input to the stock 45A converter/charger that charges the AGM bank was removed from this load center, and instead is fed through the AC-2 output of the Victron inverter (which only passes AC and is never inverted), to avoid a death-loop. Thus, the AGMs only charge from shore power or the Onan generator, never from the inverter or the Lithium batteries.)

A Nations 280XP 280A alternator was added under the hood, and wired to the Lithium bank via 4/0 cabling. A dash switch allows you to turn the alternator off or place it in low-power mode, and dash indicators monitor its state.

The entire mess was terminated using two Victron Lynx Distribution panels with requisite fusing. Because I apparently suffer from an obsessive/compulsive disorder, each input and output is separately fused and runs through a manual Blue Sea Marine disconnect switch, as well as through automated relays getting instruction from an AM Solar BMS, to control appropriate charges and loads based upon Lithium battery temperature and other operating conditions. [Shout out to AM Solar, who patiently endured countless idiotic questions from me and supplied much of the hardware at competitive pricing.] There is a fairly complex Lithium qualification loop I created, which is probably clearer from the schematics than text will allow here.

AC Management: The stock ATS toggles between shore power and the stock Onan generator, and then feeds a new Progressive Industries hardwired EMS (with remote display) to monitor and qualify incoming AC power, before it is routed to the AC systems. These each run through Blue Sea circuit breakers too. When the Onan generator is running, its trigger output is fed to the Victron inverter signal inputs to automatically limit maximum current usage accordingly.

Solar: The stock Zamp single channel solar controller was replaced with a dual channel model, which isolates its two outputs and feeds each bank separately while never allowing cross-talk. I recognize that the Zamp is only a PWM controller, and is somewhat less efficient than a comparable MPPT controller. However, given the massive charging sources we have from the Victron inverter/charger and the Nations alternator, solar is merely an afterthought – primarily coming into use when the vehicle is parked somewhere off-grid while we are hiking. We generally do not boondock for extended periods, instead moving around frequently, allowing the underhood generator to quickly provide most charging we need. This is especially true given that Winnebago installed only 200W of solar panels, and littered the roof with things in an aggressively-haphazard topography that leaves very little room for more panels. Finally, the new Zamp controller was able to fit in the old panel cutout perfectly, making it the clear choice!

Monitoring: A Digital MultiControl GX panel and pair of Victron BMV-712 battery monitors (with separate shunts on each of the AGM and Lithium banks) allow me to keep an eye on everything.

Miscellaneous: I deemed the stock Start-Assist (a/k/a Boost) switch inadequate for our split system, so a new circuit and switch, using a second relay, was crafted. Flyback diodes were utilized on all relays. A Trik-L-Start was added, with a cutout switch and separate fusing.

If my wife asks, the system was quite economical.

For completeness, vehicle is a 2017 Winnebago ERA 70A (2016 Sprinter EXT chassis) fairly stock, which we purchased used in November 2018 with approximately 4K miles.

Thank you.

|

Awesome, this is exactly the setup info I have been looking for the reason's you have outlined. My 2016 Roadtrek CS Adventurous currently has four AGM's, along with a second alternator and 270 watts of Solar. I have a 2500 Watt inverter/charger that is capable of running my roof air. I would like add around 600 to 800 AH's of Lithium batteries to my configuration in a hybrid setup.

|

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

|

» Recent Threads

» Recent Threads |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|