|

|

03-06-2023, 12:56 PM

03-06-2023, 12:56 PM

|

#1

|

|

Platinum Member

Join Date: Oct 2022

Location: Red-Neck Riveria - (Fort Walton Beach, FL)

Posts: 283

|

External Regulator on Chevy "Stock" Alternator

External Regulator on Chevy "Stock" Alternator

This may seem an "Odd" question, but there will be some sense to it as I progress with my project:

Has anyone added an external regulator (Balmar - or other e.g.; booster's Ample Power SAR v3) to the "Stock" Alternator?

I believe booster's experience may be most germane as his regulator will drive dual alternators, but I want to know if others have too.

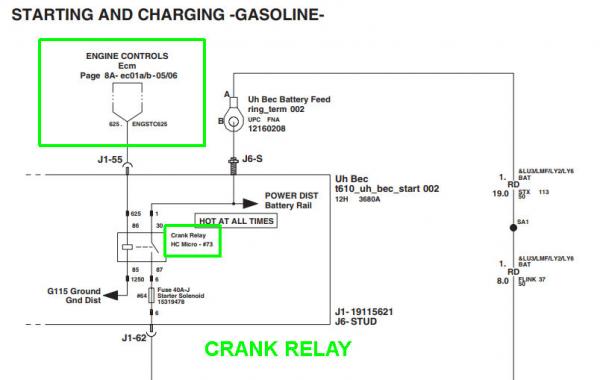

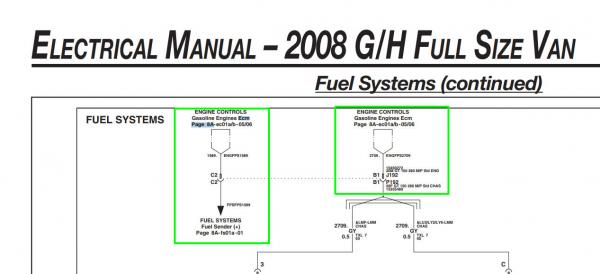

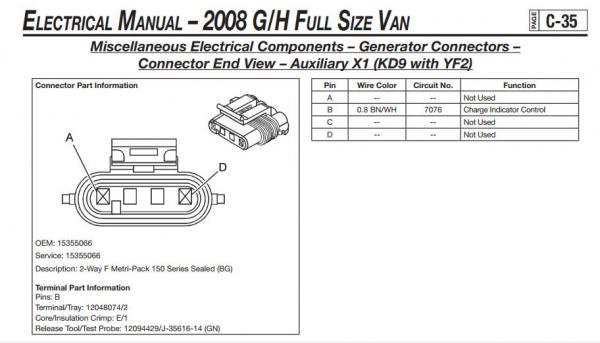

My concern is; there are 2 connections on the Chevy Van Alternator that are linked to the Ecm (Electronic control module). see images below:

I searched through the 300+ pages of the 2008 Electrical Manual, and come up with only two other locations these controls connect to. One connects to the Ecm Crank Relay, the other to fuel controls.

So, if you have added an external regulator, and eliminated the 2 connections to the Alternator - has everything been OK? Or was there something else you were required to accomplish? Did you have a special adapter cable? Any part numbers, etc are most welcome.

Thanks in advance.

Cheers - Jim

|

|

|

03-06-2023, 01:19 PM

03-06-2023, 01:19 PM

|

#2

|

|

Platinum Member

Join Date: Aug 2010

Location: Minnesota

Posts: 12,457

|

Quote:

Originally Posted by phantomjock

This may seem an "Odd" question, but there will be some sense to it as I progress with my project:

Has anyone added an external regulator (Balmar - or other e.g.; booster's Ample Power SAR v3) to the "Stock" Alternator?

I believe booster's experience may be most germane as his regulator will drive dual alternators, but I want to know if others have too.

My concern is; there are 2 connections on the Chevy Van Alternator that are linked to the Ecm (Electronic control module). see images below:

I searched through the 300+ pages of the 2008 Electrical Manual, and come up with only two other locations these controls connect to. One connects to the Ecm Crank Relay, the other to fuel controls.

So, if you have added an external regulator, and eliminated the 2 connections to the Alternator - has everything been OK? Or was there something else you were required to accomplish? Did you have a special adapter cable? Any part numbers, etc are most welcome.

Thanks in advance.

Cheers - Jim |

You pix seem to be only thumbnail size it would be nice if you could host the pix onsite and put them inline full size. If you need specific steps to do that, just PM me and I will go through them. Basically, you use the "manage attachments" section below the posting box, upload pix to the site with it and they show up in manage attachments area. Right click on the link and copy image link in the box that comes out. The paste that copy into the attach image area above the posting box which is the yellow one with the mountain.

I will need to look at my 2007 FSM again as it has been many years since I did the first round conversion to a single standalone alternator on our van and I think your 2008 may be the first of the pcm controlled ones. Ours was on an internal regulator so it was easy to do. IIRC, it does have a "field current" feed back to the pcm but I think that may just do the idiot light or maybe idle speed. If you have full charging field current control from the pcm, I think it gets more complicated and why later versions, like Dick's 2009, are using standalones on a remote regulator.

|

|

|

03-06-2023, 02:36 PM

03-06-2023, 02:36 PM

|

#3

|

|

Platinum Member

Join Date: Oct 2022

Location: Red-Neck Riveria - (Fort Walton Beach, FL)

Posts: 283

|

booster:

Interesting - They are loaded in my album here onsite.

Took the image link from there (as per other forums with same "engine").

I will edit and resize. Thanks for the offer.

DONE

Cheers - Jim

Ops test:

If you pull the image from your album - check for a "t", just before the file type "jpg" That will load as a thumbnail.

|

|

|

03-06-2023, 03:17 PM

03-06-2023, 03:17 PM

|

#4

|

|

Platinum Member

Join Date: Oct 2022

Location: Red-Neck Riveria - (Fort Walton Beach, FL)

Posts: 283

|

A cross post rather than repeat...

A cross post rather than repeat...

Here is a link to the 2008 Electrical manual for the Chevrolet G/H Full size Vans:

https://www.classbforum.com/forums/f...tml#post145706

Cheers - Jim

|

|

|

03-06-2023, 03:34 PM

03-06-2023, 03:34 PM

|

#5

|

|

Platinum Member

Join Date: Oct 2022

Location: Red-Neck Riveria - (Fort Walton Beach, FL)

Posts: 283

|

As a consequence of division...

As a consequence of division...

When I searched the document, I keyed on "ALternator" my concern. But then while splitting the manual into 2 pieces to share, I came across the "Generator" wiring.

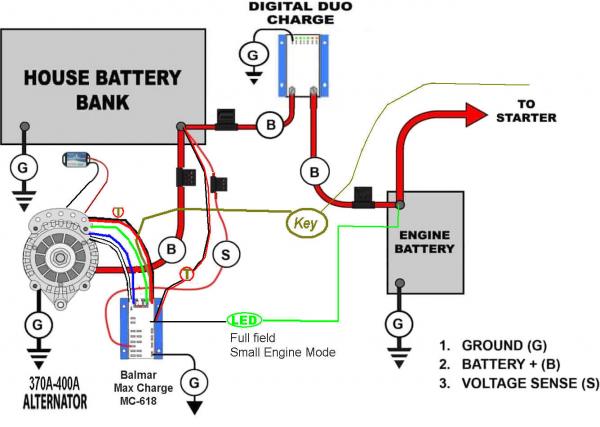

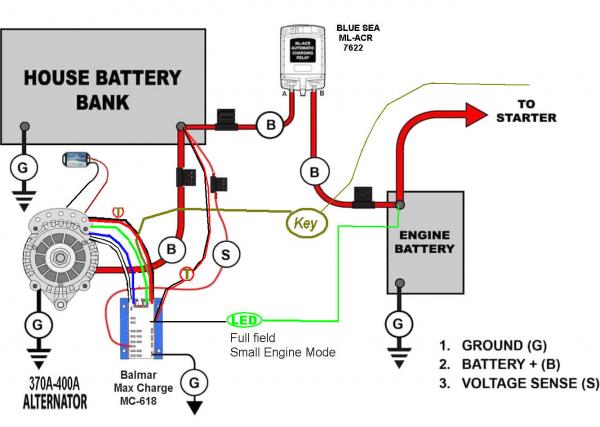

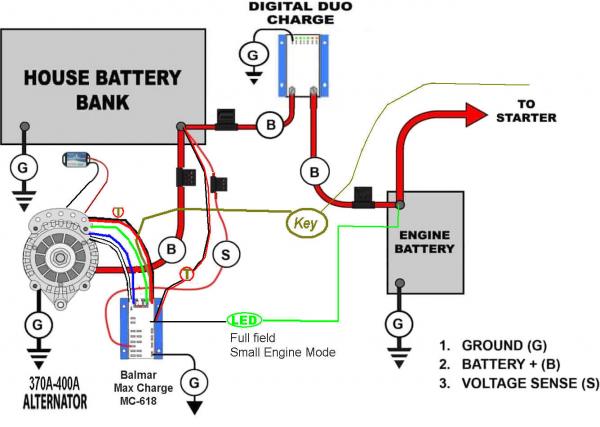

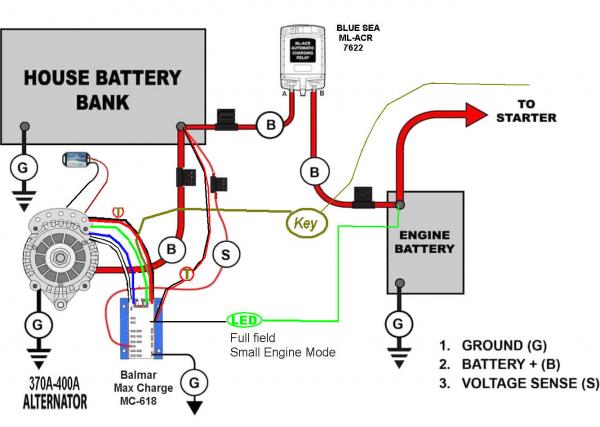

Here are 2 noteworthy images;

and,

My immediate concern is what are 1 & 2 "doing" and why are they in the image? Are they just conveniently wrapped in the same harness? I suspect so, but don't know what they are attached to...yet.

Cheers - Jim

|

|

|

03-06-2023, 04:00 PM

03-06-2023, 04:00 PM

|

#6

|

|

Platinum Member

Join Date: Aug 2010

Location: Minnesota

Posts: 12,457

|

I think the mystery is getting deeper as I just checked on Rock Auto and the alternator for your van they list is an AC Delco 3351236 which is also what they show for our van and it is listed for 2005-2012 years. It has an internal regulator.

I think Dick told me that his was PCM controlled in his 2009 and that information might have come from Adam at Nations. Hopefully, he will jump in and clear it up for certain.

The wiring diagram you posted was contrary to them being the same, though in not showing the internal regulator, but it does show the same two wires to PCM as our diagram does.

You would probably have to remove the alternator to pull the regulator cover off to see what you really have.

|

|

|

03-06-2023, 04:42 PM

03-06-2023, 04:42 PM

|

#7

|

|

Platinum Member

Join Date: Aug 2010

Location: Minnesota

Posts: 12,457

|

I blew up both electrical diagrams, yours and mine, and the actual connections to to two wires go to basically the same places as so do the stator connections. It may be that the square box in your drawing just didn't get labeled as the regulator and shows some internal connections that the small box for 07 doesn't.

Nations shows the same alternators for 2007 and 2008 but doesn't look like it doesn't for 2009 so that would explain ours being the same and Dick's being different if that is the case.

If this is the case, you would OK with parallel. I don't recall if I have the two wires connected to anything, but I will try to find out. I have a huge file of information on the last update that included the dual alternator setup so it probably will be a bit hard to find and those wires may not be included. Thing are working as normal though because the alternator trouble lamp on the dash does come on while the Ample regulator is in soft start mode.

|

|

|

03-06-2023, 06:05 PM

03-06-2023, 06:05 PM

|

#8

|

|

Platinum Member

Join Date: Oct 2022

Location: Red-Neck Riveria - (Fort Walton Beach, FL)

Posts: 283

|

Was hoping to "belay" that move. On closer examination, the #2 in the "Generator Connector" image is just a harness tie-down. The mystery is what does #1 connect to?

There is another "Connector End View" in the Part 1, that shows 2 wires. One is for the Field (Green), the other for the "Generator Turn On Signal (Orange).

|

|

|

03-06-2023, 06:11 PM

03-06-2023, 06:11 PM

|

#9

|

|

Platinum Member

Join Date: Jun 2011

Location: western New York State

Posts: 224

|

Quote:

Originally Posted by booster

I think the mystery is getting deeper as I just checked on Rock Auto and the alternator for your van they list is an AC Delco 3351236 which is also what they show for our van and it is listed for 2005-2012 years. It has an internal regulator.

I think Dick told me that his was PCM controlled in his 2009 and that information might have come from Adam at Nations. Hopefully, he will jump in and clear it up for certain.

The wiring diagram you posted was contrary to them being the same, though in not showing the internal regulator, but it does show the same two wires to PCM as our diagram does.

You would probably have to remove the alternator to pull the regulator cover off to see what you really have.

|

Unfortunately, Dick doesn't know for sure whether or not he has a PCM controlled alternator. However, my 2009 factory manual does show the same two wires (#23 & #225) that you guys have.

Not to rain on anybody's parade but in my opinion, it is better to have two separate, stand-alone systems. Here's my reasoning:

1) As long as you are retaining the stock alternator (which is not what Booster did), then it and whatever stock regulator it has can continue to serve the Chevy systems as intended.

2) The new dual alternator and Balmar regulator can serve the camper systems as intended, and you're not mixing different battery chemistries and "requirements".

3) Futzing with the ECM (or TCM or BCM) can lead to mucking it up. Don't ask how I know, but a new BCM is $500+. : (

4) By having two separate systems and having those connected to your Blue Sea switch (which you would normally keep off!), if either system fails for whatever reason, you can then connect them together easily; nice backup.

As always, YMMV.

|

|

|

03-06-2023, 06:16 PM

03-06-2023, 06:16 PM

|

#10

|

|

Platinum Member

Join Date: Oct 2022

Location: Red-Neck Riveria - (Fort Walton Beach, FL)

Posts: 283

|

What I'm "leaning" toward, is an external regulator (Balmar) with a single, drop-in, high capacity externally regulated alternator. My thinking is:

I'd rather spend the time, effort and money on that approach. I'd need to add a means to charge both House and Start. It is do-able, and price works about the same for the extra bits as buying a dual alternator bracket, with all of its installation complexities.

I understand the High Temp issues: and the failure concerns. The high temp should be monitored and controlled by the Balmar unit(s).

I'll post in a separate thread the details of that "Phase."

Cheers - Jim

|

|

|

03-06-2023, 06:30 PM

03-06-2023, 06:30 PM

|

#11

|

|

Platinum Member

Join Date: Jun 2011

Location: western New York State

Posts: 224

|

Quote:

Originally Posted by phantomjock

What I'm "leaning" toward, is an external regulator (Balmar) with a single, drop-in, high capacity externally regulated alternator. My thinking is:

I'd rather spend the time, effort and money on that approach. I'd need to add a means to charge both House and Start. It is do-able, and price works about the same for the extra bits as buying a dual alternator bracket, with all of its installation complexities.

I understand the High Temp issues: and the failure concerns. The high temp should be monitored and controlled by the Balmar unit(s).

I'll post in a separate thread the details of that "Phase."

Cheers - Jim

|

"There is a ring of truth in what you say." I have been reviewing the photos and correspondence I had with Booster in 2016-17 when we were both working on the dual alternator installations, and "the degree of difficulty" was definitely into double digits. Perhaps you can rig your system up to directly charge the house Lithium's and use a DC-to-DC charger from that to your Chevy battery.

|

|

|

03-06-2023, 06:52 PM

03-06-2023, 06:52 PM

|

#12

|

|

Platinum Member

Join Date: Aug 2010

Location: Minnesota

Posts: 12,457

|

Quote:

Originally Posted by dicktill

Unfortunately, Dick doesn't know for sure whether or not he has a PCM controlled alternator. However, my 2009 factory manual does show the same two wires (#23 & #225) that you guys have.

Not to rain on anybody's parade but in my opinion, it is better to have two separate, stand-alone systems. Here's my reasoning:

1) As long as you are retaining the stock alternator (which is not what Booster did), then it and whatever stock regulator it has can continue to serve the Chevy systems as intended.

2) The new dual alternator and Balmar regulator can serve the camper systems as intended, and you're not mixing different battery chemistries and "requirements".

3) Futzing with the ECM (or TCM or BCM) can lead to mucking it up. Don't ask how I know, but a new BCM is $500+. : (

4) By having two separate systems and having those connected to your Blue Sea switch (which you would normally keep off!), if either system fails for whatever reason, you can then connect them together easily; nice backup.

As always, YMMV.

|

Can't argue with any of this as there are really few applications where you would get the bigger benefit out of parallel. High rate charging and not thermal cycling were top priorities to me and having parallel has a big advantage there. If you turn down the regulator as far you can with a Balmar which, I think down to 40-50% you still may get into thermal cycling if the engine compartment is hot with the standalone setup. If you want above about 160 amps of charging to the coach when you are at the normal weather limit, from what I have seen on out alternator temps when I still had sensors on them. If you really want to hit the batteries hard, if they will accept it without damage as we can get 280 amps continuous for about 20 minutes in normal weather, but we found we never have needed that so I reset our regulator from 180 and 280 amps switchable to 120 and 180 amps and it has been just about right as we can still get a quick charge in a short time that is enough for a day or two of use.

I do think the high amp charging thing when you start talking about over 180 amps is not a likely to be wanted as it was when I built our system. Back then, those that were going to lithium had been told that they could charge at very high rates. 5C in amps if they wanted to so most every lithium system could easily accept the approximately 300 amps that 4/0 cable with handle and then some. But now times have changed and the lithium manufactures have pretty severely moved the max charge rates down a whole lot in many cases. .4C is now pretty common and that is also what Lifeline gives for preferred charge rate after a deep discharge in AGMs. A 400ah lithium bank would only be able to take 160 amps and that is within a single alternator running continuously in most weather conditions. It takes a really big system to charge at even 300 amps at .4C and many of the big watt hour systems are going to 24-48 volts.

All this said, if I did a single standalone I would certainly turn it down as far as you can with a Balmar so it minimizes the thermal cycling. Dick has done this, as I remember, and I think has two stages of turn down as you can do that by putting switches in the right places and getting the setting correct to match. I wish they would make it 20-100% adjustable like the Ample Power (Charles) was. I would not just run a single alternator with an internal or non adjustable output regulator on it.

There is a new regulator out also that I have quickly looked at that might be able to do everything better. If it has good turndown and battery and alternator temp compensations it would be ideal. I will have to see if I can find it again. Now that I have a yet untested spare Ample Power it is of less of a priority to find something else.

On thing to be sure of is that if you do the battery switch to connect the system you would need to make sure the second alternator was out of the loop so the regulators don't fight each other and that may or may not be and issue with internal or PCM controlled setups. Emergency use only I would say.

|

|

|

03-06-2023, 07:01 PM

03-06-2023, 07:01 PM

|

#13

|

|

Platinum Member

Join Date: Aug 2010

Location: Minnesota

Posts: 12,457

|

Quote:

Originally Posted by phantomjock

Was hoping to "belay" that move. On closer examination, the #2 in the "Generator Connector" image is just a harness tie-down. The mystery is what does #1 connect to?

There is another "Connector End View" in the Part 1, that shows 2 wires. One is for the Field (Green), the other for the "Generator Turn On Signal (Orange).

|

The two wires in the 4 pin connector is typical of how they did that as the used the same connector for everything on alternators it appears. One is the start sense and the other is feeback to the PCM that doesn't really seem to do much that I have been able to find out.

|

|

|

03-06-2023, 07:31 PM

03-06-2023, 07:31 PM

|

#14

|

|

Platinum Member

Join Date: Aug 2010

Location: Minnesota

Posts: 12,457

|

OK here is the newest remote regulator. It says it senses battery and alternator temps and TAPERS the charging so it doesn't get any better than that. If it can handle two alternators (identical) parallel it would work well for that and it would be perfect for a single independent setup.

https://www.wakespeed.com/product/ws...ab-title-specs

|

|

|

03-06-2023, 10:00 PM

03-06-2023, 10:00 PM

|

#15

|

|

Platinum Member

Join Date: Oct 2022

Location: Red-Neck Riveria - (Fort Walton Beach, FL)

Posts: 283

|

Continued --pulling back the curtain - just a bit...

Continued --pulling back the curtain - just a bit...

In some regards, I am getting ahead of myself, and peddling faster to catch up!

[quote] [booster] High rate charging and not thermal cycling were top priorities to me and having parallel has a big advantage there. If you turn down the regulator as far you can with a Balmar which, I think down to 40-50% you still may get into thermal cycling if the engine compartment is hot with the standalone setup.[quote]

Likewise. My dual Lithium batteries are both 260Ah, and have a 250A BMS. So "pounding" them I don't expect as a problem. Engine bay heat can be dealt with, to a degree (intended). A purpose built rear cooling duct, augmented with a fan and thermostat control, could go a long way to keeping the alternator cool.

I've been looking, and leaning further into the Balmar Digital Dual Controller.

It meets much of the criteria booster outlined here:

[quote]t says it senses battery and alternator temps and TAPERS the charging so it doesn't get any better than that. If it can handle two alternators (identical) parallel it would work well for that and it would be perfect for a single independent setup.

Here I've added a bunch of the other wiring I'll need to work. Also included the Balmar "Alternator Saver:"

I've kicked around keeping the Blue Sea ACR in the circuit, but it gets complicated. And room for mistakes (man-in-the-loop).

The ACR approach has a secondary problem of 'Amp-load." The Balmar Digital Duo, limits the charging to the starting battery to 30 amps.

The big thing, as a DIY-guy, there is a heap of work that I can avoid if I went to a Dual Alternator setup. And engine bay temps are no less with a second alternator pumping out amps either.

BTW, Adam quoted that new alternator (Wakespeed), but I am trying to get past the ecu. It connects to the CAN Bus (or maybe just an option?).

I have a draft write up of what I've posted here that outlines my DM process. Will post later. Just now, I'm beat to my socks. I've been working under the van (on the driveway) to install the propane solenoid.

Cheers - Jim

|

|

|

03-06-2023, 10:32 PM

03-06-2023, 10:32 PM

|

#16

|

|

Platinum Member

Join Date: Aug 2010

Location: Minnesota

Posts: 12,457

|

[QUOTE=phantomjock;145730]In some regards, I am getting ahead of myself, and peddling faster to catch up!

[quote] [booster] High rate charging and not thermal cycling were top priorities to me and having parallel has a big advantage there. If you turn down the regulator as far you can with a Balmar which, I think down to 40-50% you still may get into thermal cycling if the engine compartment is hot with the standalone setup.[quote]

Likewise. My dual Lithium batteries are both 260Ah, and have a 250A BMS. So "pounding" them I don't expect as a problem. Engine bay heat can be dealt with, to a degree (intended). A purpose built rear cooling duct, augmented with a fan and thermostat control, could go a long way to keeping the alternator cool.

I've been looking, and leaning further into the Balmar Digital Dual Controller.

It meets much of the criteria booster outlined here:

Quote:

t says it senses battery and alternator temps and TAPERS the charging so it doesn't get any better than that. If it can handle two alternators (identical) parallel it would work well for that and it would be perfect for a single independent setup.

Here I've added a bunch of the other wiring I'll need to work. Also included the Balmar "Alternator Saver:"

I've kicked around keeping the Blue Sea ACR in the circuit, but it gets complicated. And room for mistakes (man-in-the-loop).

The ACR approach has a secondary problem of 'Amp-load." The Balmar Digital Duo, limits the charging to the starting battery to 30 amps.

The big thing, as a DIY-guy, there is a heap of work that I can avoid if I went to a Dual Alternator setup. And engine bay temps are no less with a second alternator pumping out amps either.

BTW, Adam quoted that new alternator (Wakespeed), but I am trying to get past the ecu. It connects to the CAN Bus (or maybe just an option?).

I have a draft write up of what I've posted here that outlines my DM process. Will post later. Just now, I'm beat to my socks. I've been working under the van (on the driveway) to install the propane solenoid.

Cheers - Jim

|

I don't think that the Digital Duo Charge does the stuff I talked about as it is really just about transferring and limited amount of charge to the starting battery, I think 30 amps. Other than that it would use it's not very good preprogrammed algorithm for profile.

With 520ah of lithium you will need to limit current to the batteries as they will accept way over what even 500 amps of alternator and the wiring will be able to handle. Is you BMS designed to fully control the charging and coach ouput separately? That is necessary if cycling off the BMS as it is fully charged and shuts off completely you would get a big spike, which you might even get anyway if the current isn't limited or tapered way down. Most systems that have an external regulated standalone alternator would have some sort of cutout in the circuit to kill the alternator output when charging is done so that the coach connection stays live. The other option is a B to B charger but you would need at least a couple of them for high rate changing and be able to shut them off or have a lithium profile that shuts them off.

Of course the issue of what you batteries are rated to absorb has to come to play as on those batteries that have a lower max charge rate it is always way lower than what they will absorb. The big question on the Wyco regulator is how they handle the turndown and if you can have it start at a lower output than wide open. My guess is that it will shut off once a threshold is reached in lithium profile mode, but you would need to not shut off two alternators as you lose the engine being powered.

The controls for lithium batteries is much more complex than for AGMs, and it has been discussed on here many, many times.

To get the control you will need and profile you need, it may make it pretty much necessary to go with one big single alternator and current limiting or auto tapering based on battery and alternator temps if the Wyco can do that well.

|

|

|

03-06-2023, 11:48 PM

03-06-2023, 11:48 PM

|

#17

|

|

Platinum Member

Join Date: Oct 2022

Location: Red-Neck Riveria - (Fort Walton Beach, FL)

Posts: 283

|

booster - Once again thanks - a lot to process and I'll be on it shortly. Just a few quick ones:

Quote:

|

I don't think that the Digital Duo Charge does the stuff I talked about as it is really just about transferring and limited amount of charge to the starting battery, I think 30 amps. Other than that it would use it's not very good preprogrammed algorithm for profile.

|

Perhaps a useful alternative to charge the start battery would be a B2B?

Quote:

|

With 520ah of lithium you will need to limit current to the batteries as they will accept way over what even 500 amps of alternator and the wiring will be able to handle.

|

The BMS is internal. Each of the 2 have a 250A charge/discharge limit. Net at 500 Amps. I anticipate we'd never hit over 400Amps from any alternator - given the footprint constraint. And, factor in turn down/temperature limitations, the only real reason for that size would be to have the "excess capacity" and heat sink to survive.

Quote:

|

...BMS as it is fully charged and shuts off completely you would get a big spike, which you might even get anyway if the current isn't limited or tapered way down. Most systems that have an external regulated standalone alternator would have some sort of cutout in the circuit to kill the alternator output when charging is done so that the coach connection stays live.

|

I'm pedaling... faster, faster, faster... Yes Balmar has an Alternator Protection Module that I intend to add just for that purpose.

Quote:

|

The other option is a B to B charger but you would need at least a couple of them for high rate changing and be able to shut them off or have a lithium profile that shuts them off.

|

yes - a B2B could be an option. Would it have a charge profile? I don't know - not familiar, but will research some more before I pull out the CC!

Quote:

|

The controls for lithium batteries is much more complex than for AGMs, and it has been discussed on here many, many times.

|

Cant say I've read them all, but my eyes bleed...

Quote:

|

To get the control you will need and profile you need, it may make it pretty much necessary to go with one big single alternator and current limiting or auto tapering based on battery and alternator temps if the Wyco can do that well.

|

Two points here; Not familiar with a Wyco Regulator. And, yes. Tapering/tailoring the Balmar Charging profile seems to work. I got this from Winston in response to a small email survey I sent out:

Quote:

|

We won't spend much time in this (first) response discussing charging profiles. But we've decided that a Constant Voltage charge profile is desirable for lithium batteries so we 'jury-rigged' the Balmar regulator to be a Constant Voltage supply. We did this by programming the Bulk charge period for the Balmar to be 8 hours (way longer than we'd ever drive in one sitting. Thus the Balmar remains in Bulk mode . . . and we simply set the Bulk voltage to the desired Constant Voltage).

|

My two fingers are sore. Later.

Cheers - Jim

|

|

|

03-07-2023, 12:07 AM

03-07-2023, 12:07 AM

|

#18

|

|

Platinum Member

Join Date: Aug 2010

Location: Minnesota

Posts: 12,457

|

Quote:

Originally Posted by phantomjock

booster - Once again thanks - a lot to process and I'll be on it shortly. Just a few quick ones:

Perhaps a useful alternative to charge the start battery would be a B2B?

The BMS is internal. Each of the 2 have a 250A charge/discharge limit. Net at 500 Amps. I anticipate we'd never hit over 400Amps from any alternator - given the footprint constraint. And, factor in turn down/temperature limitations, the only real reason for that size would be to have the "excess capacity" and heat sink to survive.

I'm pedaling... faster, faster, faster... Yes Balmar has an Alternator Protection Module that I intend to add just for that purpose.

yes - a B2B could be an option. Would it have a charge profile? I don't know - not familiar, but will research some more before I pull out the CC!

Cant say I've read them all, but my eyes bleed...

Two points here; Not familiar with a Wyco Regulator. And, yes. Tapering/tailoring the Balmar Charging profile seems to work. I got this from Winston in response to a small email survey I sent out:

My two fingers are sore. Later.

Cheers - Jim

|

Thing to remember that an abrupt shutdown of the batteries will also damage your van electronics and if you have solar it will leave no reference and it will spike also. Same will happen when you have shore power if the charger doesn't see it and not start. If it is already running when they shut down the charger will spike.

This is why a using the BMS only for an emergency backup lockout is a better choice, or having and setup that separates the charge and discharge sides so the charging can be shut down by the batteries or controls and the coach stays active.

If the the batteries cut out completely there has to be a way to get them to come back on line safely which can be a challenge sometimes.

Pretty complex to be sure, and why the fully integrated systems exist. All of the above is why if my AGMs die, I will be replacing with the same as I can just plunk them in and be good to go, and they work just fine for us.

B to B chargers will work, but I think the largest is 120 amps right now and they lose about 20-25% to efficiency losses so output is less than 120 amps. That is why a regulator that reduces the alternator output at the field and also sets a good profile is my preference.

Also consider that the 250 amp max charge rate per battery is just surge, they should also give a max continuous to prevent overheating. That is again a reason that if the Wyco regulator does sense battery charging temp and cut the output amperage to stabilize the temp in the battery (or alternator) without heat cycling, it would be really a nice unit. You won't know what your max continuous charge rate is until you get in process measurements. Hope your BMS has a temp output to use so it is accurate.

|

|

|

03-07-2023, 01:07 PM

03-07-2023, 01:07 PM

|

#19

|

|

Platinum Member

Join Date: Oct 2022

Location: Red-Neck Riveria - (Fort Walton Beach, FL)

Posts: 283

|

Quote:

|

Thing to remember that an abrupt shutdown of the batteries will also damage your van electronics and if you have solar it will leave no reference and it will spike also. Same will happen when you have shore power if the charger doesn't see it and not start. If it is already running when they shut down the charger will spike.

|

Van electronics? No GPS/LORAN/RADAR/Autopilot/Speed/Wind/Depth/no NMEA2000 system. Maybe the TV? Laptop should be able to handle with internal battery. No Solar.

Quote:

|

This is why a using the BMS only for an emergency backup lockout is a better choice, or having and setup that separates the charge and discharge sides so the charging can be shut down by the batteries or controls and the coach stays active.

|

OK, isn't that why a high rated BMS is used to ensure you don't bump over the top? And yes, I do envision using the BMS only as the emergency lockout. Keeping the charging voltage below the combined BMS of 500A, the actual charging closer to 250-275A due to engine bay heat, should keep that well in the "green." For discharge, the 3000 Watt inverter is "over sized for actual requirements today, and the 6000Watts available (250*12) should be enough "headroom" too.

Quote:

|

If the the batteries cut out completely there has to be a way to get them to come back on line safely which can be a challenge sometimes.

|

Acknowledged. (and in some regards, I am mildly surprised a "Lithium Battery - Jump Pack" has not been marketed for this purpose.

Quote:

|

Pretty complex to be sure, and why the fully integrated systems exist. All of the above is why if my AGMs die, I will be replacing with the same as I can just plunk them in and be good to go, and they work just fine for us.

|

Fully integrated systems? Links please (mind you for this platform an RT - not Airstream/Suburban/etc.). I have had a "bit"of experience integrating systems, and have yet seen something here. Not intended as an insult - I am earnestly curious about the suggested "integrated system."

Quote:

|

B to B chargers will work, but I think the largest is 120 amps right now and they lose about 20-25% to efficiency losses so output is less than 120 amps. That is why a regulator that reduces the alternator output at the field and also sets a good profile is my preference.

|

The B2B role would be just charge the starting battery 650-850 CCA. Not so much required, I'd think.

Quote:

|

Also consider that the 250 amp max charge rate per battery is just surge, they should also give a max continuous to prevent overheating. That is again a reason that if the Wyco regulator does sense battery charging temp and cut the output amperage to stabilize the temp in the battery (or alternator) without heat cycling, it would be really a nice unit. You won't know what your max continuous charge rate is until you get in process measurements. Hope your BMS has a temp output to use so it is accurate.

|

Naah. This is a problem with internal BMS - is its all hidden. No adjustments, no measurements, just like an SLA. It is, what it is. Understanding the charge/discharge use will be well below the BMS max capacity ought to be "safe."

Still Questioning? Who/what/where is; WYCO Regulator? Is this the mfgr. of the Wakespeed Regulator that Nation's sells? If so, I thought that was Dragonfly?

I have a post for the choice/options and my DM on the project. Your thoughts - post here or stand alone and link from-to here?

TIA

Cheers - Jim

|

|

|

03-07-2023, 01:58 PM

03-07-2023, 01:58 PM

|

#20

|

|

Platinum Member

Join Date: Aug 2010

Location: Minnesota

Posts: 12,457

|

Answers in red.

Quote:

Originally Posted by phantomjock

Van electronics? No GPS/LORAN/RADAR/Autopilot/Speed/Wind/Depth/no NMEA2000 system. Maybe the TV? Laptop should be able to handle with internal battery. No Solar.

OK, isn't that why a high rated BMS is used to ensure you don't bump over the top? And yes, I do envision using the BMS only as the emergency lockout. Keeping the charging voltage below the combined BMS of 500A, the actual charging closer to 250-275A due to engine bay heat, should keep that well in the "green." For discharge, the 3000 Watt inverter is "over sized for actual requirements today, and the 6000Watts available (250*12) should be enough "headroom" too.

Yes, the BMS should be used for emergency trip only, IMO, but you also need a way to terminate the charging as lithium doesn't like to floated or overcharged. The norm would be to use a full cutoff charger to do that for shore power or generator but you would need to also do something for the engine charging. Also be aware that no charging should be allowed under about 35*F.

Acknowledged. (and in some regards, I am mildly surprised a "Lithium Battery - Jump Pack" has not been marketed for this purpose.

A jump pack would get the charger to activate, but depending on the cause of the trip out, it might not restart the batteries. Low and high temp trips are probably the common, but they can also shut down if they get too discharged. The low discharge there usually needs to be some kind of reset procedure to bring them online without a jumppack or other source of charge and some shut off charging capability also I think.

Fully integrated systems? Links please (mind you for this platform an RT - not Airstream/Suburban/etc.). I have had a "bit"of experience integrating systems, and have yet seen something here. Not intended as an insult - I am earnestly curious about the suggested "integrated system."

The biggest and most common one is Victron as it is a major part of their business. They use their dealers and installers to determine what is needed for a fully integrated system. They seem to have a very high competency in the newest system controls, especially with lithium. They almost certainly will not be inexpensive though. Their major market is in the boats and high end motorhomes.

The B2B role would be just charge the starting battery 650-850 CCA. Not so much required, I'd think.

If you do that it will be good to get profile, but you still will need to limit the charging amps to the coach lithium batteries as they will accept way more than the alternators and wiring will handle.

Naah. This is a problem with internal BMS - is its all hidden. No adjustments, no measurements, just like an SLA. It is, what it is. Understanding the charge/discharge use will be well below the BMS max capacity ought to be "safe."

As I mention above the limiting of amps is to prevent overheating the wiring and alternators long before hitting the amps max of the BMS. We have found that with a 250 and 280amp units in parallel that we limit at about 180 amps before the alternators go over 225* which is a commonly chosen limit for good alternator life. If you do lots of extra cooling, which is hard on the Chevy, I have looked at it, you might get a bit more but I doubt you could get to 250-275 continuously, though. Belt load may also become an issue at some point especially when the engine compartment starts to get hot, which it will when climbing long and steep grades. Add in the belt load from the AC being on and you might get into an issue running long periods of time.

Still Questioning? Who/what/where is; WYCO Regulator? Is this the mfgr. of the Wakespeed Regulator that Nation's sells? If so, I thought that was Dragonfly?

I am not sure about exactly who is behind it. The first time I saw an early one I saw one it was referred to as Wyco in and article as an upcoming product and it stuck in my mind, I guess, the website is Wakespeed and is the one I linked above. I assume they are the same product, but there was no pic or detailed specs originally. Many others besides Nations are now pushing it instead of the Balmar, it appears, based on the Wakespeed website. Dragonfly is one of them recommending them. Dragonfly is also the parent of Battleborn.

I have a post for the choice/options and my DM on the project. Your thoughts - post here or stand alone and link from-to here?

Link on here would be good for all to see, I think.

One thing for consideration, that you may have already done. Having a predicted use pattern with energy needs and capacity based on that pattern is very useful. It can help prevent over and under designing the system and make sure that use, storage, and recovery all match. I missed on ours in relation to the recovery needs in terns of charge rates and times. I figured we would need the 180 amps continuous charging and also the 280 amp fast recovery. In real use we have found that we essentially never needed the 280 amps and only rarely use the 180 amp charge rates. Probably 98% of the time we are running it in the now available 120 amp mode when it is running. A lot of the time it is actually turned off because the solar is capable of taking over the final charging once we get to low enough acceptance on the batteries. Both the alternators and the batteries run cooler that way and that is a good thing.

TIA

Cheers - Jim

|

|

|

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

|

» Recent Threads

» Recent Threads |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|