|

|

03-07-2023, 02:12 PM

03-07-2023, 02:12 PM

|

#21

|

|

Platinum Member

Join Date: Aug 2010

Location: Minnesota

Posts: 12,457

|

It appears the Wakespeed Offshore got acquired by Dragonfly in May of 2022.

Wakespeed Offshore is/was part of TJC Micro and was owned partially by a guy that came from Ballard, which is Balmar. I find nothing on TJC Micro so Wakespeed must have been all of them. I didn't find anything on the other owner(s) as it appears most of that has disappeared with the acquisition. It certainly makes sense that someone from Balmar, who was in sales management it appears, would know what the customers were asking for and the weaknesses of the Balmar, which we all know of.

|

|

|

03-07-2023, 02:24 PM

03-07-2023, 02:24 PM

|

#22

|

|

Platinum Member

Join Date: Aug 2010

Location: Minnesota

Posts: 12,457

|

On the Wakespeed website there was also a statement about them doing fully integrated systems, so they probably going for the same market as Victron.

|

|

|

03-07-2023, 07:50 PM

03-07-2023, 07:50 PM

|

#23

|

|

Platinum Member

Join Date: Oct 2022

Location: Red-Neck Riveria - (Fort Walton Beach, FL)

Posts: 283

|

Options/Choices/Decisions - Why am I asking the previous ??s

Options/Choices/Decisions - Why am I asking the previous ??s

This is "late" in the posting. My initial intent was to solve a nagging question regarding upgrading the stock alternator and using an external regulator. But we've gone so far down track it just makes sense to be here.

My approach is based on my 35+ years cruising/sailing experience, building several 1000Ah+ battery systems (self and friends), with various charging regimes. These involved charging from shore, single and dual alternator setups, solar, wind, and water. Each had its merits. Now with my land-based "cruiser," I'll forgo any wind and water charging, and put solar on the back burner.

For my decision making, I am seeking to charge a 520Ah of lithium battery bank (ironically almost at the useful capacity I had worked with previously with AGM/Gels.)

In considering the Single vs Dual Alternator, I first reviewed the common items to each, and then each of the 2 options.

Common items

400Amp Alternator

I'm considering a high capacity alternator to provide the 60-67 percent lower amp production which can be expected as alternator warms. When this occurs, a Balmar regulator (with Alternator Temperature Sensing) can cut back the output to protect the alternator. With a 400Amp Alternator, output should be about 250 Amps continuous. [Perhaps as low as 180 suggested by booster] An interesting value to consider for the wiring runs to the aft (house) battery bank. I have yet to determine if the stock alternator is a 2 - or - 4 pin. More and more, it looks like 2 of the 4 pins are used - so its a 2 pin. https://www.classbforum.com/forums/f...tml#post145730

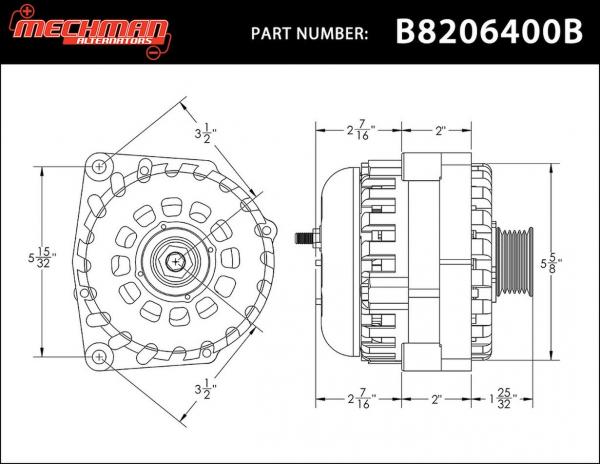

Here is a "sample" of what I believe is available. But will Call!

Similar setups have posted specs like: Amperage 370 AMPS

Max amps hot 310

IDLE amps 250

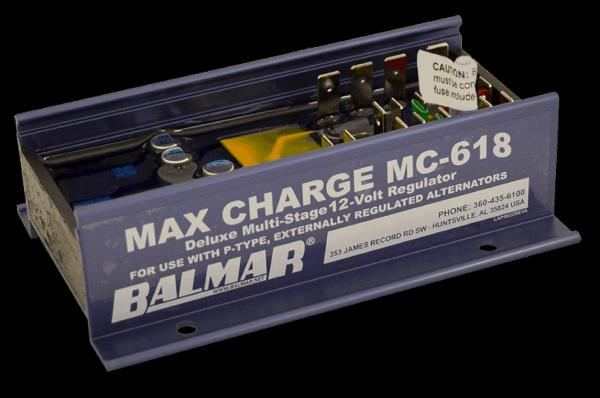

IDLE amps hot 225 Balmar MC-618

This is the latest variant of the Balmar external regulators. These and earlier versions seem highly regarded by the ClassB community. There is a 50% mode that can be engaged with a switch to reduce output and therefore heat in the alternator. I understand, it integrates battery and alternator temperature into its charging. I am familiar with its first generation as a Xantrex, complete with the quirky magnetic switch setting.

[i]Balmar Alternator Protection Device APD[/]

In the event the high capacity alternator needs to be shutdown, this device prevents a surge/spike from damaging the alternator. A worthy piece of insurance, and easy to install.

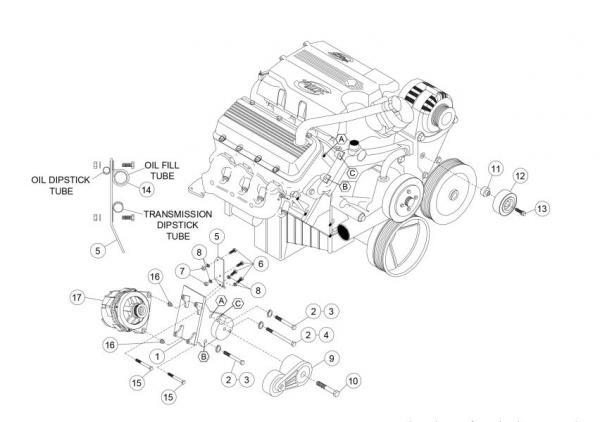

Items specific to a Dual Alternator System

Items specific to a Dual Alternator System

[i]Bracket Kit[/]

The choices seem to be brackets on passenger side or driver's side. Each has it own challenges. From what I understand, the passenger side is a Royal PITA to install. It either requires some relocation of existing air conditioner/heater equipment/valves, etc., or may require modification of the bracket itself. Davetill was very kind and shared a bunch of his pictures from his installation. Milling required and still a PITA!

On the other hand, there are some interesting brackets available for driver's side installation. My cursory look indicates the steering linkage is "very" close, and the firewall could be a problem.

Hmm. As the saying goes, it can't be a project until there is blood, and cost & schedule are busted!

Single Alternator "Upgrade"

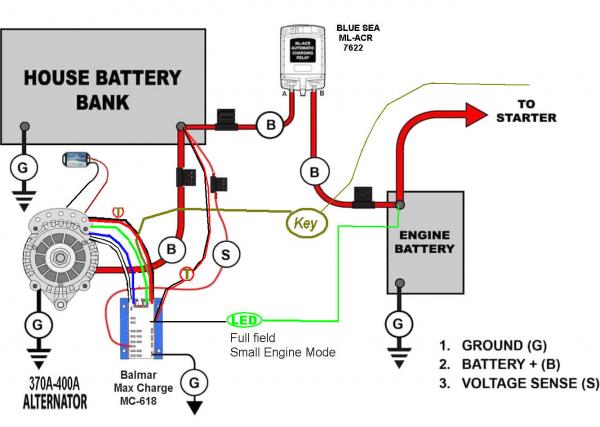

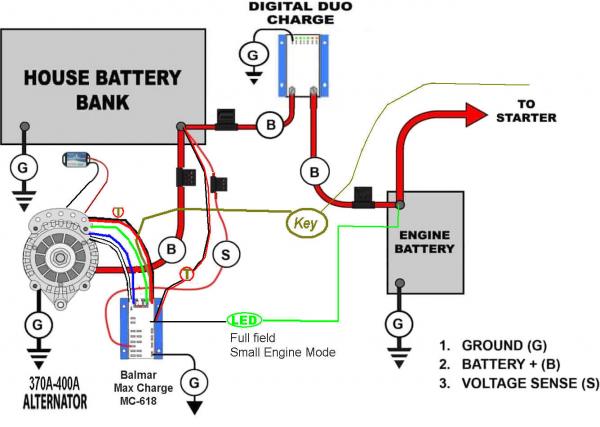

The challenge to installing a large capacity (Amp) alternator first is fitment, second integrating an external regulator (Balmar), and not over taxing the small starting battery, while charging the House Bank. The "reduced" load option of the Balmar could allow charging of both, but at 50% of alternator output. NOTE: This can be a switch on the dash, and engaged when the alternator temps rise. I have installed a dual readout gauge during PHASE-1. When charging, once the starting battery is topped up, the Blue Sea ML-ACR could manually disconnect the starting battery. With the start battery "isolated" the alternator could allow the Balmar to charge the House Bank at a higher rate. This is a "man-in-the-loop" setup, and also not without its possible complications. A missed cue, could destroy an alternator or overcharge a battery. Neither a good option. An alternative process could be begin charging with the start battery disconnected, charge the House, and when temps rise (as they will do) engage reduced charging mode. Then the start battery.

As I was researching, I came across another device; Balmar Digital Duo Charge (DDC-12/24)

From their literature:

Provides a “hands off” solution for charging two battery banks without the use of problematic isolatrs or manual battery switches. ... Eliminates the Need for an Isolator, Relay or Manually Operated Battery Switch.

During charging the DDC-12/24 monitors voltage at the house battery. When voltage exceeds the set minimum (typically 13.2V in a 12V system and 26.4V in a 24V system) the DDC-12/24 automatically engages, providing up to 30A charge current to the starting battery. When no charge source is present, the DDC-12/24 separates the batteries so the starting battery won’t be accidentally discharged into the house battery. ...House and Start Batteries can be different technologies... When no charge source is present, the DDC-12/24 separates the batteries so the starting battery won’t be accidentally discharged into the house battery.

Now the down side, I would no longer require the recently installed Blue Sea ACR. In addition to buying a bunch of "stuff," the price for the Balmar DDC-12/24 is about the same as a dual bracket! I still would need to sort out the integration of a Single High Capacity Alternator with the Balmar MC-618. For example, can I disconnect the existing ECU link (if any) to the regulator, and go with just the external Balmar? TBD Much discussion previous in this thread...

My "lean" is more and more towards the single alternator implementation. A drop-in High Capacity (will require some phone calls), a Balmar MC-618 external Regulator, Balmar Digital Duo Charge, and a Balmar Alternator APD. I'd most likely pull the Blus Sea ACR and its switch, and reuse that real estate for the DDC, the Balmar "off switch", and other support LED on dash, etc..

Other options - B2B vs DDC

All to be determined pending alternator charging issues discussed earlier.

Still to be resolved: Can I replace the "stock/ECU-controlled" alternator with an external regulator and a high-capacity alternator--and not wind up with more complications other than throwing a "code?"

Meanwhile, I'll be working the install of the lithium frame and batteries today as time and weather permits.

|

|

|

03-14-2023, 04:02 PM

03-14-2023, 04:02 PM

|

#24

|

|

Platinum Member

Join Date: Oct 2022

Location: Red-Neck Riveria - (Fort Walton Beach, FL)

Posts: 283

|

OK, time for a clean sheet of paper.

What I know now:

1. My Alternator to Battery Charger (400Amps) would destroy all but the largest alternators available (as Lithium Batteries have little to no resistance) - so much for salvaging parts from my sailboat!

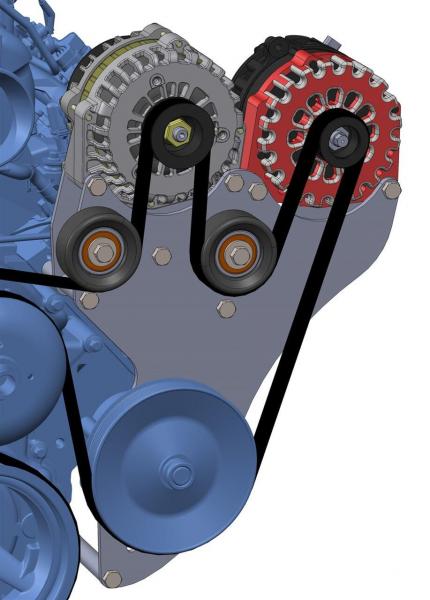

2. This suggests then a second alternator dedicated for the Lithium House Bank a. There is limited space for a second alternator on the Driver's side

b. The possibilities of a second alternator on the passengers side is "fair" at best. Some members have done this, but it was described as a PITA(model dependent). 3. Maybe upgrading the Alternator and use an external regulator. I worked with a major Alternator manufacturer, and we settled on a 300-ish alternator, but he could not recommended using it with an external regulator. So, a split system is out.

This brings me to an often recommended solution - DC to DC, aka Battery to Battery (B2B) Charger. booster suggested the current available size is around 120 Amps. Less than I'd desire, but you can't always get what you want. But if you try...

I have sourced a possible solution!

The B2B can be down rated to accommodate the stock alternator, while I get the upgrade sorted out. Nice to be more or less on track.

Comments, observations? I'm wide open and haven't pulled out the plastic yet.

TIA.

Cheers - Jim

Yes - I owe pics and updates for the DASH and now, the undercarriage mount of the LiFePO4 battery bank. Sooon.

|

|

|

03-14-2023, 10:00 PM

03-14-2023, 10:00 PM

|

#25

|

|

Platinum Member

Join Date: Aug 2010

Location: Minnesota

Posts: 12,457

|

Quote:

Originally Posted by phantomjock

OK, time for a clean sheet of paper.

What I know now:

1. My Alternator to Battery Charger (400Amps) would destroy all but the largest alternators available (as Lithium Batteries have little to no resistance) - so much for salvaging parts from my sailboat!

2. This suggests then a second alternator dedicated for the Lithium House Bank a. There is limited space for a second alternator on the Driver's side

b. The possibilities of a second alternator on the passengers side is "fair" at best. Some members have done this, but it was described as a PITA(model dependent). 3. Maybe upgrading the Alternator and use an external regulator. I worked with a major Alternator manufacturer, and we settled on a 300-ish alternator, but he could not recommended using it with an external regulator. So, a split system is out.

This brings me to an often recommended solution - DC to DC, aka Battery to Battery (B2B) Charger. booster suggested the current available size is around 120 Amps. Less than I'd desire, but you can't always get what you want. But if you try...

I have sourced a possible solution!

The B2B can be down rated to accommodate the stock alternator, while I get the upgrade sorted out. Nice to be more or less on track.

Comments, observations? I'm wide open and haven't pulled out the plastic yet.

TIA.

Cheers - Jim

Yes - I owe pics and updates for the DASH and now, the undercarriage mount of the LiFePO4 battery bank. Sooon. |

Very smart to get away from the 400 amps of charging. A 120 amp B to B will either take 20% more power than that to run it at full output or the it will be 20% lower than 120 if it goes that way. I don't recall which way they have it.

But, IMO, a better solution would be to get a bigger than 220 amp alternator of a standalone 280. On your model it appears that both could be run on a single remote alternator with dual or as a big single if you decide you can get enough charging that way. I would count on limiting current, including running the van which can easily get to 50 amps with climate control blower on high and or with the headlights on, to 65% of rated capacity unless you can rig special ventilation like you mentioned earlier. That might get you some extra. A 280 amp single as a standalone second alternator would give about 165 net average amps to the coach without overheating, from what I have seen. That is a good spot to be with 400ah of batters as you can get a couple of days use of capacity back in an hour. Any loads in the van like a frig or charging devices would also add on, but with a standalone on the coach the stock alternator will take care of the van fine.

Lots of choices except for remote regulators which would be either Balmar or Wakespeed. The remote regulators don't waste the 20% of the alternator output, so I prefer them very much over a B to B.

|

|

|

03-14-2023, 10:39 PM

03-14-2023, 10:39 PM

|

#26

|

|

Platinum Member

Join Date: Oct 2018

Location: MN

Posts: 520

|

Quote:

Originally Posted by booster

Very smart to get away from the 400 amps of charging. A 120 amp B to B will either take 20% more power than that to run it at full output or the it will be 20% lower than 120 if it goes that way. I don't recall which way they have it.

.

|

Sterling has new B2B models. The claimed efficiency is 95 to 98% for the 120A model. It's bidirectional too.

Others with which I'm familiar have similar efficiencies.

|

|

|

03-14-2023, 11:12 PM

03-14-2023, 11:12 PM

|

#27

|

|

Platinum Member

Join Date: Aug 2010

Location: Minnesota

Posts: 12,457

|

Quote:

Originally Posted by @Michael

Sterling has new B2B models. The claimed efficiency is 95 to 98% for the 120A model. It's bidirectional too.

Others with which I'm familiar have similar efficiencies.

|

When I looked into it a few years ago, what I found when I questioned Sterling and others about why folks were seeing 20% losses when specs were much less, they said that the specs are based on the max efficiency point which is much lower output than full load efficiency and 20% is possible at full output. I know inverters rate the same way so totally plausible. I think Rowiebowie sees about 20% on his B to B, IIRC.

The certainly may have improved them as I have not looked into it recently as I much prefer doing limiting at the alternator regulator because it easy and no loss of output. It would be interesting to see some testing of a new Sterling to see how efficient they are at max output.

|

|

|

03-15-2023, 06:31 PM

03-15-2023, 06:31 PM

|

#28

|

|

Platinum Member

Join Date: Oct 2022

Location: Red-Neck Riveria - (Fort Walton Beach, FL)

Posts: 283

|

booster - Once again you have some good info, and give me some more “homework!” All appreciated and thanks.

Yep. I understand regulating at the alternator as a preferred point of action. It can quickly integrate alternator temperature, and the output can be adjusted for line loss to the bank, assuming it has a sense line from the bank. All good in the situation with an externally regulated alternator, and you are familiar with some of the ones I have used previously.

But now, I’m dealing with an internally regulated alternator, managed by the ECU/etc., which presents a different opportunity. As would, adding a second alternator. Mind you, I have used single and dual alternator setups with and without external regulators - in my previous life. Now, I’m just trying to tip-toe my way through this newly discovered minefield of Lithium-powered shore-based cruising.

Generally, what would be involved in two apparently separate scenarios? How are they the same/different?

Scenario ONE - Dual Alternator

Purchase - 2nd Alternator - of appropriate amperage (a good time to consider a rebuild on the original or replace it + belt, and other under-hood chores)

Purchase - Dual mounting Kit

Purchase - External Regulator

Purchase - Alternator Protection Device

Installation - At best, difficult.

Mechanical Rating maybe 4 of 5 "wrenches?" [Plus, milling]

Cable runs, wiring, etc., easy peasy. Scenario TWO - One Alternator

Purchase - Upgraded Alternator - of appropriate amperage.

Purchase - Battery - to - Battery Charger - of appropriate amperage

Purchase - Alternator Protection Device

Installation - Moderately difficult.

Mechanical Rating maybe 2 1/2 of 5 "wrenches?" [Alternator swap only]

Cable runs, wiring, B2B install, etc., easy peasy. Costs:

Alternator costs should be a "push."

Alternator Protection Device - same/same

External Regulator and Dual installation brackets [WAG: $550-$750+] (probably low)

Pending the size of the B2B Charger, could run upwards of One BOAT-buck ($1K) (They seem to scale as; a 50% increase in price yields a 66% increase in capability. Not a bad trade-off)

Advantages: Both scenarios provide charging to the house bank. Efficiencies can be debated and considered, but once understood, can be factored in the design, purchase choices, and installation. Installation of either scenario is within my personal capability - so I have no excuses there.

Scenario ONE: a backup alternator "online and ready to go. (I've never had an alternator failure in 35+ years of cruising. Starters-yes. Opps, I've said it again!)

Scenario TWO: a spare alternator removed and ready to install if required.

Marginal weight, cost, and long term maintenance required for either scenario.

Each will have its proponents or adherents. (Some people like pie - others cake. Both are fattening but good)

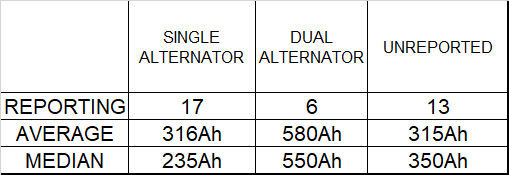

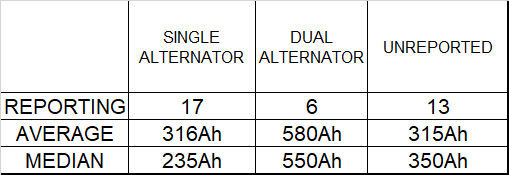

In the "survey" elsewhere in the forum, I found the following interesting results:

The high average Ah banks reported by Dual Alternator Setup is moderated by examining the median. A few “heavy hitters” skew the average, Over half of the Dual Alternator users (reported) have between 500 and 800Ah banks. Also not shown, are the numbers of those that had the second alternator professionally installed, or purchased originally as an option. In an after-market (my situation) that would represent an even greater expense. Although I could maybe justify it with; “…its annual maintenance, DEAR!”

In terms of efficiencies, I have made inquiries regarding that (hope to have answers soon). However, an 80% efficiency is not terrible. Not great, but not terrible. A 20% efficiency would be, however - if that is the loss reported. But not the actual efficiency as I read the post. As an aside, I note the percent of use of SOLAR as a charging method, rates at about 35% in the same survey. Whether this reflects use, efficiency, preference, or best guess, I can’t report.

Cheers - Jim

|

|

|

03-15-2023, 07:09 PM

03-15-2023, 07:09 PM

|

#29

|

|

Platinum Member

Join Date: Aug 2010

Location: Minnesota

Posts: 12,457

|

Quote:

Originally Posted by phantomjock

booster - Once again you have some good info, and give me some more “homework!” All appreciated and thanks.

Yep. I understand regulating at the alternator as a preferred point of action. It can quickly integrate alternator temperature, and the output can be adjusted for line loss to the bank, assuming it has a sense line from the bank. All good in the situation with an externally regulated alternator, and you are familiar with some of the ones I have used previously.

But now, I’m dealing with an internally regulated alternator, managed by the ECU/etc., which presents a different opportunity. As would, adding a second alternator. Mind you, I have used single and dual alternator setups with and without external regulators - in my previous life. Now, I’m just trying to tip-toe my way through this newly discovered minefield of Lithium-powered shore-based cruising.

Generally, what would be involved in two apparently separate scenarios? How are they the same/different? Scenario ONE - Dual Alternator

Purchase - 2nd Alternator - of appropriate amperage (a good time to consider a rebuild on the original or replace it + belt, and other under-hood chores)

Purchase - Dual mounting Kit

Purchase - External Regulator

Purchase - Alternator Protection Device

Installation - At best, difficult.

Mechanical Rating maybe 4 of 5 "wrenches?" [Plus, milling]

Cable runs, wiring, etc., easy peasy. Scenario TWO - One Alternator

Purchase - Upgraded Alternator - of appropriate amperage.

Purchase - Battery - to - Battery Charger - of appropriate amperage

Purchase - Alternator Protection Device

Installation - Moderately difficult.

Mechanical Rating maybe 2 1/2 of 5 "wrenches?" [Alternator swap only]

Cable runs, wiring, B2B install, etc., easy peasy. Costs:

Alternator costs should be a "push."

Alternator Protection Device - same/same

External Regulator and Dual installation brackets [WAG: $550-$750+] (probably low)

Pending the size of the B2B Charger, could run upwards of One BOAT-buck ($1K) (They seem to scale as; a 50% increase in price yields a 66% increase in capability. Not a bad trade-off)

Advantages: Both scenarios provide charging to the house bank. Efficiencies can be debated and considered, but once understood, can be factored in the design, purchase choices, and installation. Installation of either scenario is within my personal capability - so I have no excuses there.

Scenario ONE: a backup alternator "online and ready to go. (I've never had an alternator failure in 35+ years of cruising. Starters-yes. Opps, I've said it again!)

Scenario TWO: a spare alternator removed and ready to install if required.

Marginal weight, cost, and long term maintenance required for either scenario.

Each will have its proponents or adherents. (Some people like pie - others cake. Both are fattening but good)

In the "survey" elsewhere in the forum, I found the following interesting results:

The high average Ah banks reported by Dual Alternator Setup is moderated by examining the median. A few “heavy hitters” skew the average, Over half of the Dual Alternator users (reported) have between 500 and 800Ah banks. Also not shown, are the numbers of those that had the second alternator professionally installed, or purchased originally as an option. In an after-market (my situation) that would represent an even greater expense. Although I could maybe justify it with; “…its annual maintenance, DEAR!”

In terms of efficiencies, I have made inquiries regarding that (hope to have answers soon). However, an 80% efficiency is not terrible. Not great, but not terrible. A 20% efficiency would be, however - if that is the loss reported. But not the actual efficiency as I read the post. As an aside, I note the percent of use of SOLAR as a charging method, rates at about 35% in the same survey. Whether this reflects use, efficiency, preference, or best guess, I can’t report.

Cheers - Jim |

I thought we had figured out you have an internally regulated alternator in you 2008? It has a field % sensing wire to the pcm but it doesn't control charging.

I have had a couple of vehicle alternators die over the years, but we always drive our cars until they are near dead over many years and many mile so expected. RV battery charging is at high rates and extended times so not really a good comparision as a vehicle alternator would likely never see that kind of service. I think all/most marine alternators are 100% duty cycle at full load aren't they.

Converting an internally regulated one to external so you could parallel is not hard, I did ours, but you only need to do it on a parallel system. On a split system with second alternator you can get the alternator setup of external regulation so it comes with two field wires sticking out of it instead of having an internal regulator.

We have had ours both ways, bigger single and dual parallel. We have not had ours as two separate systems, but I wouldn't hesitate to that either.

My choice if given the options is first the parallel with two big alternators and a current limiting external regulator running both (as long as the van doesn't have a pcm controlled standard alternator. Second would be a second alternator as standalone and on a current limiting remote regulator. Third would be a single big regulator with current limiting device. And fourth would be a big single alternator with internal regulation and not current limiting device.

In general, with the exception of huge lithium systems and no current limiting, the second alternators have been quite durable as long as they are on a Balmar that turns them down when too hot or on a current limiting device to keep amps low enough to prevent overheating.

|

|

|

03-15-2023, 11:32 PM

03-15-2023, 11:32 PM

|

#30

|

|

Platinum Member

Join Date: Oct 2022

Location: Red-Neck Riveria - (Fort Walton Beach, FL)

Posts: 283

|

booster -

All good there. I follow your step-wise selection of options on charging choices.

I apologize for having made an error in my median analysis. This reflects the corrections:

Cheers - Jim

|

|

|

03-16-2023, 12:26 AM

03-16-2023, 12:26 AM

|

#31

|

|

Platinum Member

Join Date: Aug 2010

Location: Minnesota

Posts: 12,457

|

Quote:

Originally Posted by phantomjock

booster -

All good there. I follow your step-wise selection of options on charging choices.

I apologize for having made an error in my median analysis. This reflects the corrections:

Cheers - Jim |

I am surprised that there are that few dual setups that you found but if it doesn't include pro installs or factory that would explain a lot of it by 2015 or so lots of units were coming with them, especially Roadtreks, with a lot of them on 200ah or so some higher capacity banks. Of course a lot of posters have come and gone, also.

Even at the median amount of 235 the single alternators would need current limits if lithium. AGMs at 235ah would absorb about .4C or 94 amps continuous without overheating but likely would take more than that if given which could overheat the batteries and the alternator if higher than .4C for more than about 20 minutes.

I think all the dual ones on this forum are standalone except ours, but may have missed a couple. I do recall a couple of failures and some of those were early unregulated current ones that didn't have current limiting. I think the Nations that failed for davydd had a Balmar on it, but from the current numbers he saw it must have been heat cycling which can cause an overtemp switch failure as they aren't designed for continuous cycling. He would be able to fill in the details. He had a huge lithium back and was a very large amp hour user per day, so lots of heavy charging on his failed alternator.

I think a lot will depend on just how much charger rate you consider you minimum to cover your usage pattern with your driving or shore power pattern, plus solar if you do it.

Solar is very much a personal choice and is big advantage to top off the last 20% in AGM banks like ours to reduce the time on the charger or alternator to get to absolute full based on tail amps. Less of a benefit for lithium in time savings because the charge at higher rate all the way to full.

|

|

|

03-16-2023, 02:07 PM

03-16-2023, 02:07 PM

|

#32

|

|

Platinum Member

Join Date: Oct 2022

Location: Red-Neck Riveria - (Fort Walton Beach, FL)

Posts: 283

|

Quote:

|

I am surprised that there are that few dual setups that you found but if it doesn't include pro installs or factory that would explain a lot of it by 2015 or so lots of units were coming with them, especially Roadtreks, with a lot of them on 200ah or so some higher capacity banks. Of course a lot of posters have come and gone, also.

|

Actually, that correlation was only a result of integrating a (Lithium only user) email survey I did of those that had previously indicated they had Lithium on the forum "survey thread." I didn't get all of them, and am at almost 60% return rate, but enough to understand the numbers that are Sprinters, or ProMaster, and have different dual install issues. It was a chore to dig through the posts to find what little extra I did. (even with "smartsearch."

Quote:

|

Even at the median amount of 235 the single alternators would need current limits if lithium. AGMs at 235ah would absorb about .4C or 94 amps continuous without overheating but likely would take more than that if given which could overheat the batteries and the alternator if higher than .4C for more than about 20 minutes.

|

The LI - ONLY for the single alternators are 250Ah average and 350Ah median. The 4 that I found alternator ratings for were 150A - 250A.

Quote:

|

I think all the dual ones on this forum are standalone except ours, but may have missed a couple. I do recall a couple of failures and some of those were early unregulated current ones that didn't have current limiting. I think the Nations that failed for davydd had a Balmar on it, but from the current numbers he saw it must have been heat cycling which can cause an overtemp switch failure as they aren't designed for continuous cycling. He would be able to fill in the details. He had a huge lithium back and was a very large amp hour user per day, so lots of heavy charging on his failed alternator.

|

I do anticipate our LI bank is "overkill." It is sized for the possibility of absorption refrigeration replacement (I like/prefer compressor driven refrigeration), and the possible addition of an induction "hot plate." Not to eliminate propane, but extend its use. Then, our main limitation will be tankage, just a fact of life.

Quote:

|

I think a lot will depend on just how much charger rate you consider you minimum to cover your usage pattern with your driving or shore power pattern, plus solar if you do it.

|

Our energy use, charging rate, and ops tempo is something we'll have to experience and refine. Too soon to anticipate, but we have some planning factors. For track days, there will be travel to/from and then stay onsite. As most tracks are 400-800 miles distant, there will be a mid-travel stop or two each way. Then at the track may/may not be shore power. Duration trackside may run 3-4 days/nites then RTB.

For vacations, and exploration, we are considering 4-7 days on site before moving to next location. Travel time using the more-or-less 3/3/3, daily stop dependent. Unless visiting friends/family, these will be POI, parks, and events.

Quote:

|

Solar is very much a personal choice and is big advantage to top off the last 20% in AGM banks like ours to reduce the time on the charger or alternator to get to absolute full based on tail amps. Less of a benefit for lithium in time savings because the charge at higher rate all the way to full.

|

Trackside solar (portable) could be useful. Most paddocks are wide open (few trees) and secure. Hell, racing machines are there with a lot of pricey equipment. A folding solar panel would be low buck "heist."

Alternator/regulator control is an important and necessary ability to ensure the alternator isn't overheated through extended runtimes. I am investigating using a switch on the B2B feed to the house bank or the circuit from the alternator to the B2B, and let the alternator just charge the Start Battery, once a sufficient charge is on the House. It would be "man-in-the-loop," but if possible, as simple as shutting off the alternator as others (you?) have used in their systems. With a bt of effort an Arduino circuit could be used to monitor the alternator temp and open the circuit. A "bright-Spark" has built an Arduino PCM replacement too BTW, so things are possible. I've asked these questions, now pending answers.

Cheers - Jim

|

|

|

03-16-2023, 02:35 PM

03-16-2023, 02:35 PM

|

#33

|

|

Platinum Member

Join Date: Aug 2010

Location: Minnesota

Posts: 12,457

|

The compressor frig will likely be your biggest user unless you do the the induction plate which could really use a lot if used much.

We have had a compressor frig for over a decade and it uses in the range of 20-50 ah per day with the high end when it is very hot out, as in over 100*F and in the sun. Our total use is about 20ah per day above that.

A 280 amp coach dedicated alternator will do about 100 amps at idle in most cases, for reference, so you can get at least a days use back in an hour. You may also need to go to the dump station in 3-4 days so that would probably also be enough if you do. I assume the track would allow idling and generators? Sizing for absolutely worst case is probably not needed or cost effective as long as you can get some recovery quickly and without breaking campground rules.

You might actually be better off to carry a 20# propane cylinder to cover any propane shortage that you might get, but we rarely need to fill our tank even and never in 4 days. Just get an adapter to connect it to RV tank systems. Might be easier to save the power with the extra capacity of propane and no induction plate.

|

|

|

03-16-2023, 04:27 PM

03-16-2023, 04:27 PM

|

#34

|

|

Platinum Member

Join Date: Jun 2011

Location: western New York State

Posts: 224

|

Quote:

Originally Posted by phantomjock

I do anticipate our LI bank is "overkill." It is sized for the possibility of absorption refrigeration replacement (I like/prefer compressor driven refrigeration), and the possible addition of an induction "hot plate." Not to eliminate propane, but extend its use. Then, our main limitation will be tankage, just a fact of life.

Our energy use, charging rate, and ops tempo is something we'll have to experience and refine. Too soon to anticipate, but we have some planning factors. For track days, there will be travel to/from and then stay onsite. As most tracks are 400-800 miles distant, there will be a mid-travel stop or two each way. Then at the track may/may not be shore power. Duration trackside may run 3-4 days/nites then RTB.

For vacations, and exploration, we are considering 4-7 days on site before moving to next location. Travel time using the more-or-less 3/3/3, daily stop dependent. Unless visiting friends/family, these will be POI, parks, and events.

Trackside solar (portable) could be useful. Most paddocks are wide open (few trees) and secure. Hell, racing machines are there with a lot of pricey equipment. A folding solar panel would be low buck "heist."

Alternator/regulator control is an important and necessary ability to ensure the alternator isn't overheated through extended runtimes. I am investigating using a switch on the B2B feed to the house bank or the circuit from the alternator to the B2B, and let the alternator just charge the Start Battery, once a sufficient charge is on the House. It would be "man-in-the-loop," but if possible, as simple as shutting off the alternator as others (you?) have used in their systems. With a bit of effort an Arduino circuit could be used to monitor the alternator temp and open the circuit. A "bright-Spark" has built an Arduino PCM replacement too BTW, so things are possible. I've asked these questions, now pending answers.

|

Quote:

Originally Posted by booster

The compressor frig will likely be your biggest user unless you do the the induction plate which could really use a lot if used much.

We have had a compressor frig for over a decade and it uses in the range of 20-50 ah per day with the high end when it is very hot out, as in over 100*F and in the sun. Our total use is about 20ah per day above that.

A 280 amp coach dedicated alternator will do about 100 amps at idle in most cases, for reference, so you can get at least a days use back in an hour. You may also need to go to the dump station in 3-4 days so that would probably also be enough if you do. I assume the track would allow idling and generators? Sizing for absolutely worst case is probably not needed or cost effective as long as you can get some recovery quickly and without breaking campground rules.

You might actually be better off to carry a 20# propane cylinder to cover any propane shortage that you might get, but we rarely need to fill our tank even and never in 4 days. Just get an adapter to connect it to RV tank systems. Might be easier to save the power with the extra capacity of propane and no induction plate.

|

My "track data" is 13+ years old but I never saw shore power available anywhere in a paddock. The use of generators was allowed and widely used, usually drowned out by un-muffled race cars. Likewise, idling the tow vehicle engine wouldn't be noticed. There might be quiet hours overnight.

I would have to go back and recheck my propane data, but we camped extensively in cold and even freezing weather for many days, and the stovetop, water heater, and furnace did not run us out of propane quickly. I would not opt for an electric hot plate and would not expect to need an add-on propane tank. IMO, it would only be air conditioner usage that would kill your battery capacity.

Methinks that the black tank on your RT-170 is smaller than booster's and mine on our RT-190's; if so, that could well be your limiting factor.

|

|

|

03-16-2023, 05:30 PM

03-16-2023, 05:30 PM

|

#35

|

|

Platinum Member

Join Date: Oct 2022

Location: Red-Neck Riveria - (Fort Walton Beach, FL)

Posts: 283

|

Hey Dick -

Thanks for the info. And again, thanks for the "tool-time-tips."

I can't recall Road Atlanta, but Sebring has some 30Amp drops, but you've got to be there early. Also fortunately the "convenience" blocks include toilets and showers. It is only in the last 12-18 months they have gone to a $10 fee for campers at Sebring. Local AX is just a "wally-dock" weekend, as will be some track days.

You are right about the black (and grey tankage) being smaller in the 170 and our key LIMFAC.

The induction plate just to have a spare burner - not a replacement. Found it most convenient onboard. Won't be making that decision too quickly, however.

Curious about your propane log. Anything you'd care to share? Spreadsheet, pencil/paper? We had 3 tanks aboard and would go a looong way before needing to refill even one. But we were often away from civilization for good length of time too.

Cheers - Jim

|

|

|

03-16-2023, 06:33 PM

03-16-2023, 06:33 PM

|

#36

|

|

Platinum Member

Join Date: Aug 2010

Location: Minnesota

Posts: 12,457

|

A 170 would have an 8 gallon tank instead of a 10 gallon, but I am pretty sure Dick also has a 190.

|

|

|

03-16-2023, 09:06 PM

03-16-2023, 09:06 PM

|

#37

|

|

Platinum Member

Join Date: Jun 2011

Location: western New York State

Posts: 224

|

Quote:

Originally Posted by phantomjock

Hey Dick -

Thanks for the info. And again, thanks for the "tool-time-tips."

I can't recall Road Atlanta, but Sebring has some 30Amp drops, but you've got to be there early. Also fortunately the "convenience" blocks include toilets and showers. It is only in the last 12-18 months they have gone to a $10 fee for campers at Sebring. Local AX is just a "wally-dock" weekend, as will be some track days.

You are right about the black (and grey tankage) being smaller in the 170 and our key LIMFAC.

The induction plate just to have a spare burner - not a replacement. Found it most convenient onboard. Won't be making that decision too quickly, however.

Curious about your propane log. Anything you'd care to share? Spreadsheet, pencil/paper? We had 3 tanks aboard and would go a looong way before needing to refill even one. But we were often away from civilization for good length of time too.

Cheers - Jim

|

Quote:

Originally Posted by booster

A 170 would have an 8 gallon tank instead of a 10 gallon, but I am pretty sure Dick also has a 190.

|

Dick does in fact have a 190. Looking at a Roadtrek 2008 brochure, both 170's & 190's are listed as having the same propane capacity (10 gallons) and the same gray tank capacity (23 gallons). Differences are black tank (170 = 8 gallons, 190 = 10 gallons) and fresh water (170 = 14 gallons, 190 = 25 gallons [190 has 2 tanks]).

Here is a posting I did some time back in another group:

"We hit some ice/snow/freezing weather on our first trip (30 days total) down south in early 2011 and did just fine. We kept the inside at about 70degF and ran the fridge, water heater, and stove. We were in campgrounds more than not, so that would have cut the fridge usage. My records only showing us filling the tank once on the trip with 4.5 gallons on day 25). [edit]: In retrospect, that does seem like a long time, so maybe it was filled in between. And maybe we had an electric heater for use when we had shore power.

And we also had a run of freezing weather in Oregon on another trip: my records show getting 2.8 gallons of propane after 3 days, and 3.6 gallons after (another) 4 days; YMMV.

A gallon of propane contains a lot of energy: 84,250 Btu which is 24,691 watt-hours.

BTW, the most propane we have ever been able to cram into the "10 gallon" tank was 7.3 gallons before the overflow hissed. Might be able to get closer to the theoretical 8 gallons (80%) with the van nose a tad down. Recently we had the tank out and bled it dry; the refill was just 7 gallons."

|

|

|

06-24-2023, 02:50 AM

06-24-2023, 02:50 AM

|

#38

|

|

Platinum Member

Join Date: Sep 2022

Location: va

Posts: 101

|

@phantomjock do you have any updates? I am planning some similar upgrades.

__________________

2007 TurdWrek 190 popular

Todd

|

|

|

06-25-2023, 02:07 AM

06-25-2023, 02:07 AM

|

#39

|

|

Platinum Member

Join Date: Oct 2022

Location: Red-Neck Riveria - (Fort Walton Beach, FL)

Posts: 283

|

Quote:

Originally Posted by tlillard23

@phantomjock do you have any updates? I am planning some similar upgrades.

|

Yes and I apologize for being tardy in reporting.

I weighted the Cost/Benefit/Risk of adding a second alternator and regulator, and, and...

I settled on a Single Large Amp - drop in replacement (420 Amp Hot Rated) Alternator. It was a simple drop-in. I did some significant wiring upgrades, that should be done with that too. Frequently referred to as a 3 Big Wire Upgrade.

Because my plan was to charge 2 260aH LiFePo4 batteries in my house bank, I opted for a battery 2 Battery/DC2DC charger. These can be expensive and need to be size to the battery bank and the alternator. I purchase on that is "over the top" at 200 Amps. But CAUTION - not inexpensive - and there is an IMPORT duty too!

The alternator output can hit 200 amps at 1500 RPM, so I found and added a High Idle "kit" for my 2008/6.0L Express 170P. Slipped right in and works great. I have run the Aircon (test only - no long effort - 1 hour) on the house bank. The Alternator/B2B combo charged the bank in 1:15 hours as I recall. I am confident it would have run the Aircon on Alternator only, just as many do for a microwave. [I need to test some and report back - so somebody needs to "ask."]

So, now with my 3000W Inverter, 8000BTU Aircon (replaced the CoolCat), 420A alternator, 200A Battery to Battery DC Charger, I'm a happy Camper - well nearly so. Gotta finish the HAM rig, antenna, etc, etc..

Thank you for asking. You have sparked this (pitiful at best) response - and I'll work from this, add some pics and close out this part of my "upgrade."

Feel free to hit me with a PM for any specific questions. I'll try and be a bit more "timely."

Cheers - Jim

BTW - There are a number of fully operational items I'll be posting from this upgrade that are now excess to my requirements: Tipp-Lite; Inverter; a Blue Seas ACR, and other items.

|

|

|

06-29-2023, 06:39 AM

06-29-2023, 06:39 AM

|

#40

|

|

Platinum Member

Join Date: Sep 2022

Location: va

Posts: 101

|

Phantomjock yes! please post part numbers and relevant info, I am very interested!

__________________

2007 TurdWrek 190 popular

Todd

|

|

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

|

» Recent Threads

» Recent Threads |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|