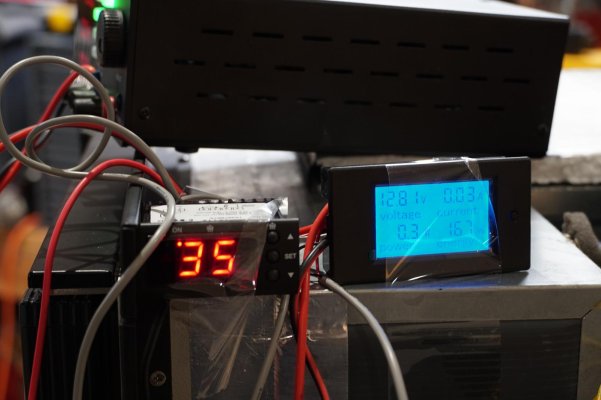

I am using the Inkbird to control the cooling fan in the electrical cabinet. This controller draws about 3W so I turn it on in hot weather only. It is wired into my battery saving switch which controls the control panel LED illumination and other not critical loads. Unfortunately, I don’t have room for its depth in possible place below the galley countertop.

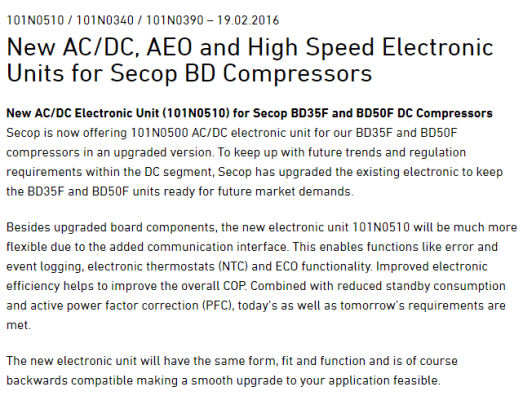

I just found this information about advantages of 101N0510 vs older 101N0500 which I have, see the picture.

I spent some time today with someone from the service department discussing my options:

- Their information about why I have 24V for the light bulb was rather fuzzy and contradicting their previous info. Danfoss instruction for 101N0500 clearly states to use 12V bulb for either 12V or 24V batteries on their spec sheet “Lamp (optional, Fig. 1) A 12V DC 5-Watt lamp (10) can be connected between the terminals A and C. The output voltage between the terminals A and C is always regulated to 12V DC. A 12V DC lamp must be used for both 12V and 24V power supply systems. The lamp output can supply a continuous current of 0.5A avg.”

- He claimed efficiency gain up to 20% using ITC vs electromechanical thermostat. Unfortunately, no details and I couldn’t find any review on line with efficiency gains.

I am going to get a new 101N0510 controller with an ITC and experiment with a location of the sensor including freezer. The risk with ITC is possible negative experience which you had but ITC has a lot of things I like:

- Turning the product on and off without opening the refrigerated

compartment Sort of, it shuts off the display and running of cooling. It doesn't go to no power or shut off the light, so is not good for storage as it still uses power and you can't ventilate the box. I just added a power on/off switch with an LED indicator of on.

- Instant display of the actual temperature inside the refrigerated

compartment Yes, but it is 2*F increments that are rounded from 1*C readings, it appears. Not particularly accurate. We use a wireless thermometer that is just fine and in 1/10*F increments and has a lithium rechargeable frig sensor.

- Display and/or change of the set temperature with a simple press of the up Yes, but in 2* increments so tough if you are trying to get close to 32* or near max at 41*.

and down keys

- Selection of permanent energy savings operation They grossly overestimate how good the savings are in either automatic or ECO. We used way, way more power in automatic that our old frig ever did once we turned down the speed, or even before. In ECO mode they say all over the place that they turn down the speed to minimum, which is 2000rpm per Secop literature, but when I saw where the amps were I went looking for an actual spec and it says they turn it down to 2500rpm. The stock speed for the mechanical was set by a 466 ohm resistor which would be about 2750rpm so very little saving there. We run at 2000 rpm almost all the time without issue as it is a small frig, added insulation, and has very good ventilation. The old frig cooled in 100*F+ in Zion while in the sun at 2000rpm. You saw the testing we did before we put it in and it used about 15% less energy on mechanical thermostat than on ECO with the ITC. I never tested the overcooling as we wouldn't want it anyway as it can damage some fresh vegetables and such. There were also a number of posts on the boater forums that said once they put it in overcooling they couldn't get it to come out without shutting down the power to the frig so glad I didn't try it.

- Instant display of any operating faults Yes

- The product is equipped with a Soft Start function. The main reason I went with the ITC against my instincts in the first place, along with a remote display. The number of

compressor revolutions is kept to the minimum allowed for approximately

30 sec. at every start of the compressor. This allows you to balance the

internal pressures on the gas circuit, preventing possible compressor blocks

and allowing the control unit to compare and process all the data set and

collected and decide whether to keep an energy-saving configuration or

increase cooling power.

- Possibility of selecting and checking the temperature within a wide-scale

range from that of the refrigerator and that of the freezer Yes, but if you go to temps you might need to reset the display temp correction factor as it has 3 ranges of temps, each with their own correction. I never tested if you can set them all up front or not, but I would hope you can.

- Possibility of selecting temperature indication in Celsius or Fahrenheit Yes, but F is a rounded off C reading converted and displays in 2* increments

- Possibility of operation with the maximum level of performance or energy

saving See above all settings, except maybe the overcooling, used considerably more energy than the mechanical does.

- Possibility of selecting 3 different battery protection levels and resulting

compressor operation

- Possibility of setting temperature offset for 3 different temperature ranges Yes

- Possibility of sub-cooling in the event of an available surplus of energy Yes