Started the engine as I normally would, with it set on low alternator output and coach batteries disconnected. Let it idle down a bit (650rpm) and then connected the coach batteries. It flashed up to about 160amps and then started dropping, so I put it on high alternator output setting and it jumped to about 210amp. The thermocouples did not go nuts and seemed to work fine. It started out reading the 280 amp alternator about 10* hotter than the 250 amp one, but by the end of the test that had swapped, with the 250 reading about the same amount hotter than the 280.

After 20 minutes was in the process of swapping, and both read 188*, with the cheapo infrared thermometer giving 202* on both in the hottest points I could get to. It was running a constant 185amps at 13.3v at that time, at 545rpm engine and 1700 rpm alternator, hood up, 65* shop temp.

At 30 minutes it was running at 200/195 on the TCs and 215/202 on the temp gun, while running at 175amps and 13.3v.

I closed the hood, and as expected, both alternators got hotter by 40 minutes. Surprisingly, they held the 175amps and 13.3v, though, and went to 215/205 on the TCs and 224/215 on the temp gun. Temp was still climbing, and I also could hear the clutch fan on the engine starting to engage, so the engine was also warming. Nearly all engines run hotter with hood closed, so no surprise there. Water temp as holding at 195*, so not at cooling capacity yet.

Just for fun, I decided to see what the add on electric cooling fans would do to the whole thing. They pull about 30 amps total when running at good voltage, so pretty big fans. They will go to near 50 amps if voltage drops. As expected, the amps to the coach dropped by the 30 amps, so total amps and volts were essentially the same, just less to the coach and batteries available. The alternator temps started dropping in less than one minute and where down about a degree per minute for the 5 minutes I let them run. This is good to know, as the alternators were cooling and we still had 145 amps to the coach available.

All of the amp numbers are the amps going to the coach, but the engine and starting battery are also running off the two alternators, so that is going to be 20+ more amps of actual output being generated. That would put us at over 2600 watts at this idle speed and temps.

Bottom line so seems to indicate that when we are into the higher temperatures, the TCs read about 10-15* cooler than the hottest spots found on the cases, which is not all that surprising. As long as it stays fairly consistent, it is an easy allowance. I forgot to get a temp of the actual alternator output terminal temp, where Balmar senses temp, but the guess would be it would also be a bit lower than the case, as it has the huge heat sink of the cable on it and it hangs out in the inlet cooling air to the alternator.

What temp is OK is certainly uncertain, I think. Balmar uses 220* at the output terminal to trigger turndown, while DC Power rates stuff at 270* alternator, but don't say where that is taken, or even if it is internal or external. Gut says using 220* on the TCs will likely be very safe, but think I will try to get an output temp at the output terminal to see how that compares to the hottest case spots. I would also expect to get substantially different temps when driving than idling, but how much and which way will interesting. Our Chevy has both alternators behind the radiator, and the added 280 amp unit is also tucked low and gets less airflow, so the Sprinters and others that hang the alternator low in the front would certainly cool better, but be more vulnerable.

At this point, at least, or risk of damage or overheating should be very low, as we can continuously see the alternator and battery temps when driving, with the option of turning the output down or off, or the fans on, if we need to. Just need to learn how they react in the driving conditions and hot weather.

Time will tell, but so far very happy with the results.

Here is pic of the stuff that is related to alternator charging, all on the dash. Basically the two channel ammeter/single channel voltmeter, 4 channel TC thermometer, the control panel which also includes the cooling fan switch, and the Blue Sea remote disconnect for the coach.

This is the control panel, showing the regulator locked into absorption, on high output setting (still only a little over 9v to the field), fans off, and coach connected.

This is the TC thermometer showing individual alternator temps, battery temperature, and oil temperature (which I have always wanted to be able to see).

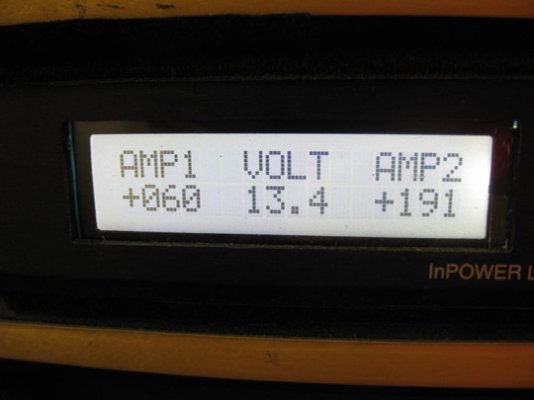

Here is the ammeter/voltmeter. The left amps are amps to the coach batteries, then voltage at the batteries, and then the total amps to the coach.

After 20 minutes was in the process of swapping, and both read 188*, with the cheapo infrared thermometer giving 202* on both in the hottest points I could get to. It was running a constant 185amps at 13.3v at that time, at 545rpm engine and 1700 rpm alternator, hood up, 65* shop temp.

At 30 minutes it was running at 200/195 on the TCs and 215/202 on the temp gun, while running at 175amps and 13.3v.

I closed the hood, and as expected, both alternators got hotter by 40 minutes. Surprisingly, they held the 175amps and 13.3v, though, and went to 215/205 on the TCs and 224/215 on the temp gun. Temp was still climbing, and I also could hear the clutch fan on the engine starting to engage, so the engine was also warming. Nearly all engines run hotter with hood closed, so no surprise there. Water temp as holding at 195*, so not at cooling capacity yet.

Just for fun, I decided to see what the add on electric cooling fans would do to the whole thing. They pull about 30 amps total when running at good voltage, so pretty big fans. They will go to near 50 amps if voltage drops. As expected, the amps to the coach dropped by the 30 amps, so total amps and volts were essentially the same, just less to the coach and batteries available. The alternator temps started dropping in less than one minute and where down about a degree per minute for the 5 minutes I let them run. This is good to know, as the alternators were cooling and we still had 145 amps to the coach available.

All of the amp numbers are the amps going to the coach, but the engine and starting battery are also running off the two alternators, so that is going to be 20+ more amps of actual output being generated. That would put us at over 2600 watts at this idle speed and temps.

Bottom line so seems to indicate that when we are into the higher temperatures, the TCs read about 10-15* cooler than the hottest spots found on the cases, which is not all that surprising. As long as it stays fairly consistent, it is an easy allowance. I forgot to get a temp of the actual alternator output terminal temp, where Balmar senses temp, but the guess would be it would also be a bit lower than the case, as it has the huge heat sink of the cable on it and it hangs out in the inlet cooling air to the alternator.

What temp is OK is certainly uncertain, I think. Balmar uses 220* at the output terminal to trigger turndown, while DC Power rates stuff at 270* alternator, but don't say where that is taken, or even if it is internal or external. Gut says using 220* on the TCs will likely be very safe, but think I will try to get an output temp at the output terminal to see how that compares to the hottest case spots. I would also expect to get substantially different temps when driving than idling, but how much and which way will interesting. Our Chevy has both alternators behind the radiator, and the added 280 amp unit is also tucked low and gets less airflow, so the Sprinters and others that hang the alternator low in the front would certainly cool better, but be more vulnerable.

At this point, at least, or risk of damage or overheating should be very low, as we can continuously see the alternator and battery temps when driving, with the option of turning the output down or off, or the fans on, if we need to. Just need to learn how they react in the driving conditions and hot weather.

Time will tell, but so far very happy with the results.

Here is pic of the stuff that is related to alternator charging, all on the dash. Basically the two channel ammeter/single channel voltmeter, 4 channel TC thermometer, the control panel which also includes the cooling fan switch, and the Blue Sea remote disconnect for the coach.

This is the control panel, showing the regulator locked into absorption, on high output setting (still only a little over 9v to the field), fans off, and coach connected.

This is the TC thermometer showing individual alternator temps, battery temperature, and oil temperature (which I have always wanted to be able to see).

Here is the ammeter/voltmeter. The left amps are amps to the coach batteries, then voltage at the batteries, and then the total amps to the coach.

Attachments

Last edited: