This past fall I performed the dreary task of swapping out my Battleborn lithium batteries for the original AGM batteries since I cannot guarantee that temperatures in my area will never get below -4 degrees F. This is a quite a pain as the batteries are located in an metal box underneath the van.

Ever since then I have been thinking about how to add a battery heater kit so that I could just turn it on, plug the vehicle in, and leave the lithium batteries installed all winter.

So this weekend I built and installed my own homebrew Lithium battery heater setup. This is how I did it:

Parts that I used:

Digital temperature controller ($12)

Heating pads ($60)

Rocker switch w/ indicator light ($9)

Long-cable temperature probe ($8)

AWG 14 wire, red ($14.5)

Heat-shrink Butt Connectors ($10)

Electrical Tape, Red ($7)

Electrical tape, Black ($9)

Yoga mat ($9)

2-Pin Waterproof 12V connectors ($9.5)

DC Fuse Kit ($13)

Tools:

Multimeter that can read DC current non-contact ($39)

Soldering Iron, 60W & kit ($17)

Assembly Notes:

Ever since then I have been thinking about how to add a battery heater kit so that I could just turn it on, plug the vehicle in, and leave the lithium batteries installed all winter.

So this weekend I built and installed my own homebrew Lithium battery heater setup. This is how I did it:

Parts that I used:

Digital temperature controller ($12)

Heating pads ($60)

Rocker switch w/ indicator light ($9)

Long-cable temperature probe ($8)

AWG 14 wire, red ($14.5)

Heat-shrink Butt Connectors ($10)

Electrical Tape, Red ($7)

Electrical tape, Black ($9)

Yoga mat ($9)

2-Pin Waterproof 12V connectors ($9.5)

DC Fuse Kit ($13)

Tools:

Multimeter that can read DC current non-contact ($39)

Soldering Iron, 60W & kit ($17)

Assembly Notes:

- First off let me state that I am not trying to keep the batteries toasty warm. My primary objective is to protect them in storage on the coldest winter days. In my area every few years we will see a nighttime temperature as low as -10 to -15 degrees F. These are the rare events I am guarding against where the internal temperature cannot be allowed to fall below -4 degrees F.

A second goal is to extend the usable season to include overnights where the temperature gets down to 20 degrees F or so. Since the batteries need to be above freezing to charge my design goal is to be able to raise the internal temperature by at least 12 degrees F through heating.

- I started by prepping the heating pads. The heating pads contain a bimetal disk temperature control switch that is normally closed but opens at 20 degrees C (68 F) and resets at 5 degrees C (41 F) (e.g. turns on again). These are notoriously unreliable and in fact when I tested them with a bag of frozen peas I found that one of the two pads I received didn't work, I could hear the switch turning off then on again repeatedly. Since I have an external controller it is best to just pull these out. To do this I pressed on the pad starting at where the wires entered it and found the small square object close by. I then cut into the pad carefully, avoiding the wires, then cut it off and replaced it with a butt splice.

- Next I tested the resistance and current for the pads. Despite being rated for 78W at 13.5V (which given P=IV and V=IR we can solve for both and see that this would mean 5.8A and 2.3 Ohms) I measured 2.6 Ohms on one and 3.0 Ohms on the other (and the expected 5.2A and 4.5A respectively in current which is only 70W and 61W of heating).

This is too much power for a battery in my opinion, I don't want to cook them or risk overheating one side. I also don't want to have 9.7A of draw whenever the are on. To reduce the power a bit I wired them in series and found that I get about 2.4A draw, which works out to about 16W of heat per pad. Hopefully this will be just about right.

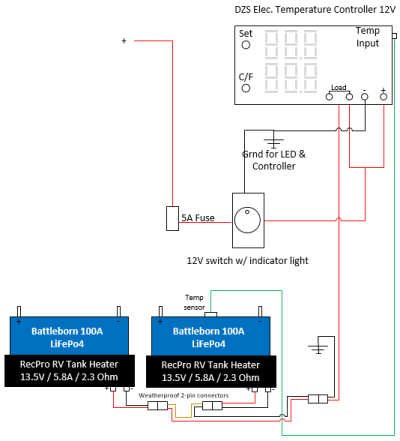

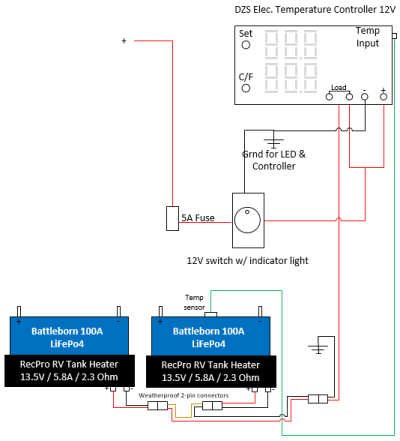

- I next installed the controller in my electrical panel. I had just added an MPPT solar controller as part of a separate project so everything was already disassembled. For power I tapped off of the solar controller battery connection. The 2.4A draw will be trivial for those AWG8 wires. I added a fuse and practiced my soldering techniques creating spliced wires to feed the controller display power and load on the positive side and a spliced wire to connect the controller display and switch light on the ground side. The rocker switch came without instructions but I eventually figured out that it needed it's own ground connection and drew power from the positive connection flowing through it.

This method had the advantage that only two wires needed to be pulled to the battery tray - the positive load wire and the temperature probe. I grabbed negative for the heating pads from a negative connection near the battery tray.

- After getting the batteries out from under the camper I applied the heating pads. The adhesive is exceptionally sticky, so rather then applying it all I cut horizontal strips in the protective backing and pulled them off so that only about 25% of the adhesive actually ends up touching the battery case. If I need to pull off the pads in the future it will not be quite so miserable of a job this way. I also added a piece of yoga mat as insulation under the battery and on the top of the battery to hold some heat. Not too much as I don't want the battery to overheat in hot conditions, but just a bit to buffer it from the cold and ensure even heating inside the battery case. I added a second thickness of yoga mat over the spot where I am inserting the temperature sensor to help ensure the measured temperature is truly coming from the battery and not the outside. The heating pads wrap around 3 sides of the battery and I left the 4th side open to promote cooling in the summer.

Next I created a wiring harness using the waterproof connectors that create the serial connection between the batteries but let me disconnect them individually or disconnect both of them. My backup plan here if the serial connection does not produce enough heat is to replace this with a parallel connection that will drive the full 9.5A into the pads. Not my preferred choice, but an option.

- I hooked everything up and ran it for two days. It is on the warmer side now, but it was about 41 degrees this morning (and climbing from a deeper low). According to the temperature probe which is located on the top of the battery at the opposite side from the heating pad the battery was at 53 degrees F. This is right about a 12 degree temperature rise and gets me a bit nervous that I don't have quite enough of a safety margin for what I want to do. The next option would be to add additional insulation. What does this group think?